Introduction

In a previously released functional specification, Strategic Automation Services (SAS) described centrifugal compressor process controls that can be executed in the Foxboro DCS using standard I/A blocks. However, that functional specification did not include details of how to implement the controls. This document provides those details. Most of the discussion in the previous functional specification is repeated here to present a more complete picture of the controls.

Anti-surge control keeps the flow through the compressor above the surge point by adjusting a blow off vent (for air blowers) or recycle control valve. The surge point is obtained from the compressor performance curves or from compressor surge testing.

Summary of Features

The SAS compressor anti-surge controls include the following features:

- Minimum control margin to define the control line.

- Variable control margin which increases the control margin when operating far away from the surge control line.

- Adaptive controller tuning to speed up response as the compressor approaches the control line.

- Asymmetrical control action to prevent the anti-surge valve from closing too fast.

- Surge line violation detection and automatic control margin increase.

These features are discussed in more detail in the following sections of this document.

Compressor Performance Curves

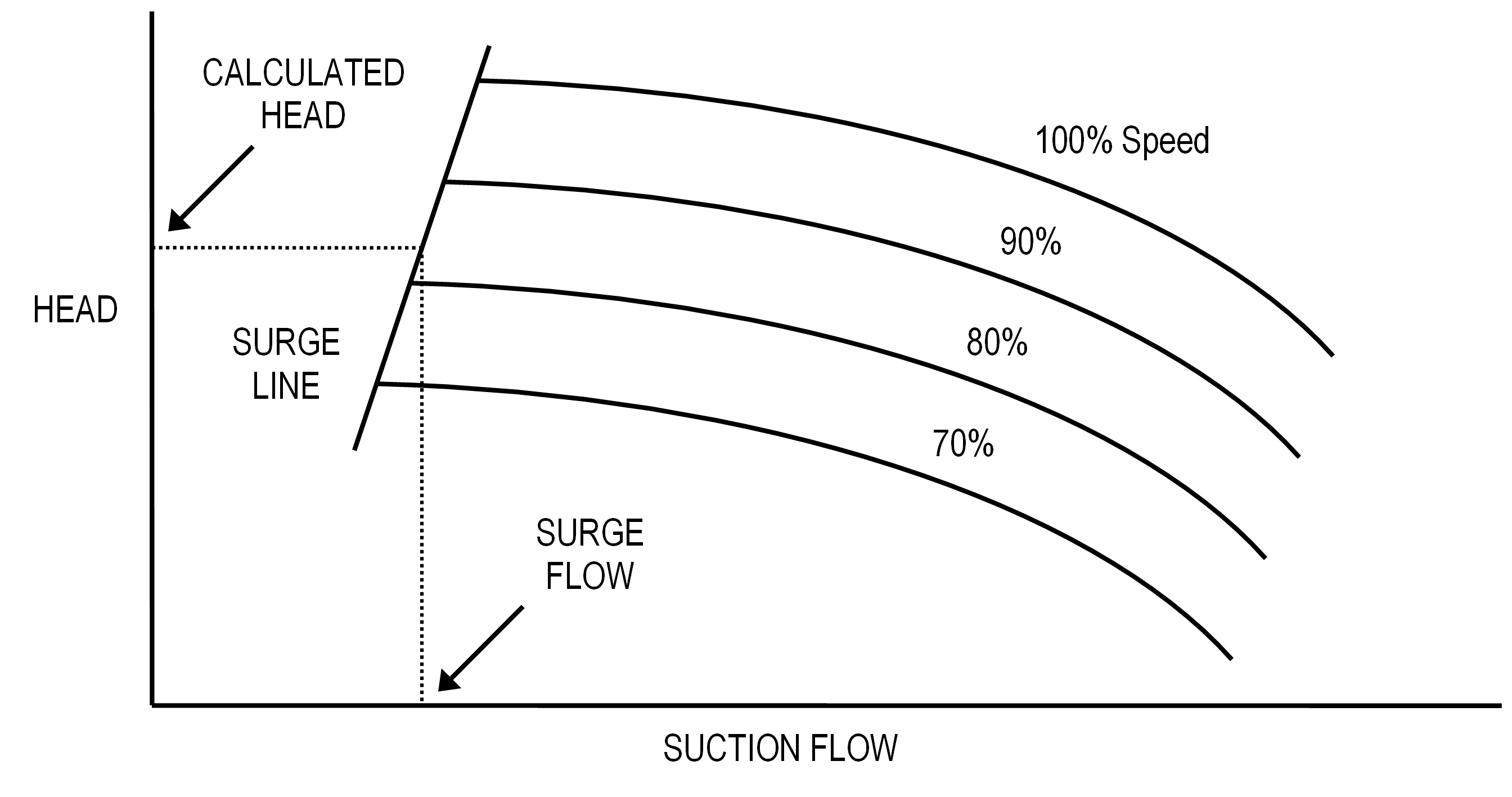

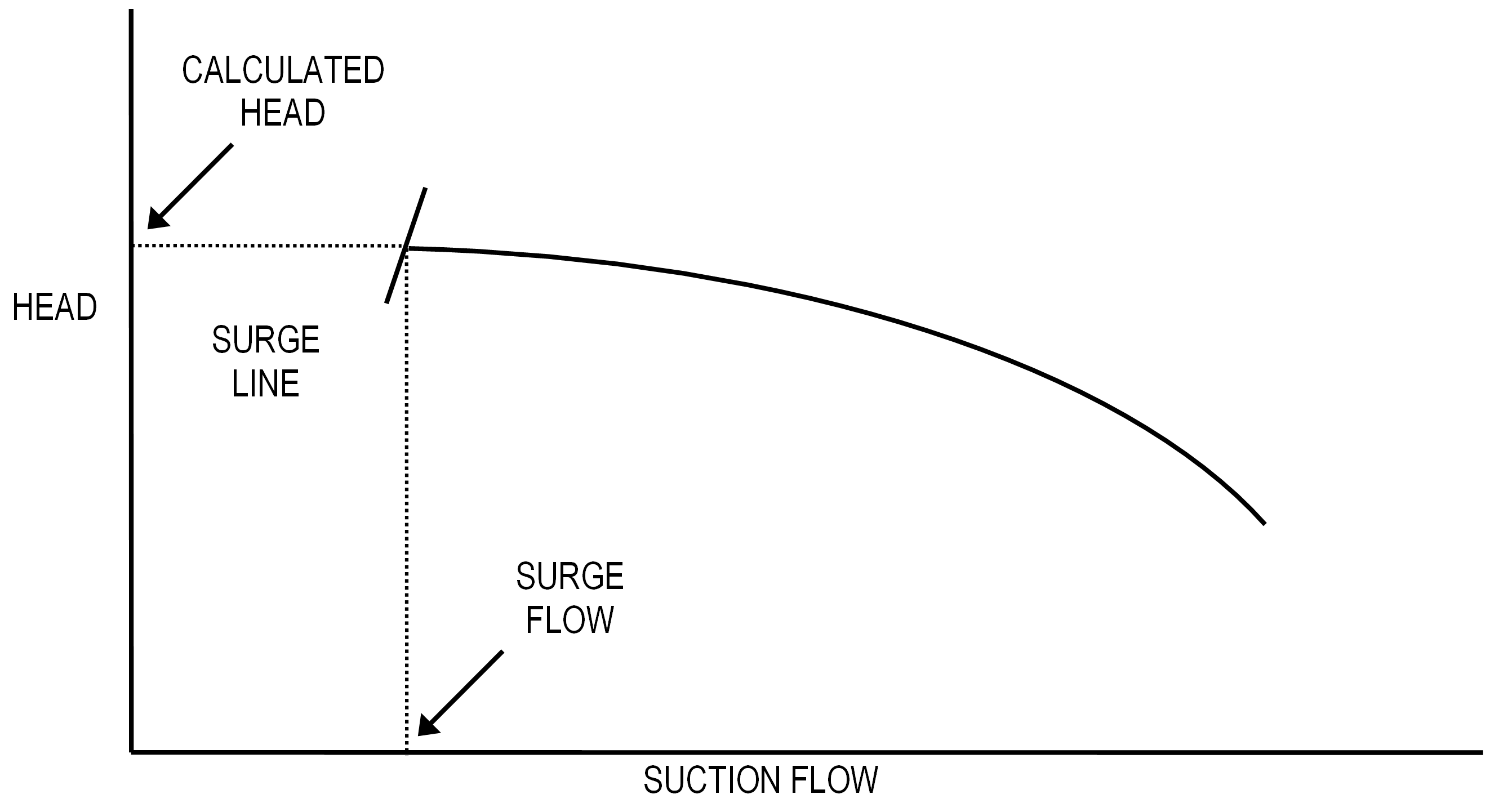

A typical performance curve for a variable speed compressor is shown in Figure 1a, and the performance curve for a fixed-speed compressor is shown in Figure 1b.

The curves show the relationship between the head generated by the compressor and the resulting flow. The relationship is inverse, meaning that as the head increases, the flow decreases, and as the head decreases, the flow increases.

At high head, the curve terminates at the surge point. If the flow is reduced below this point, the compressor suffers rapid flow reversal, which is called surge. Surge can cause extensive compressor damage if it is not quickly counteracted.

The surge points form a surge line. This line is used to determine the minimum flow through the compressor. The current head is calculated from the suction and discharge pressures, and the surge line is used to look up the surge flow.

Performance Cure Axes

The variables head and suction flow are typically used as axes for performance curves. However, the surge curve plotted on these axes is not independent of gas conditions (i.e., suction pressure, suction temperature, molecular weight). Therefore, the following parameters are used instead:

- Pressure ratio (Rc) for the y-axis.

- Suction flow orifice differential pressure corrected for pressure (hc) for the x-axis.

Surge curves plotted on these axes are relatively unaffected by changes in gas conditions. The equations for these parameters are as follows:

Rc = Pd / Ps (1)

hc = hsrg * Psr / Ps (2)

where:

Pd = discharge pressure (absolute)

Ps = suction pressure (absolute)

hsrg = suction orifice differential pressure at surge

Psr = suction reference pressure at which surge curve data was obtained

Anti-Surge Flow Setpoint Calculation – Suction Orifice

A characterizer block is used to perform a table lookup of Rc vs. hc. The suction surge flow hsrg can then be calculated by rearranging equation 2:

hsrg = hc * Ps / Psr (3)

The term hsrg is converted to suction flow as follows:

Fsrg = Fmax * SQRT (hsrg / hmax) (4)

where:

Fsrg = surge point in terms of suction conditions

Fmax = orifice flow range

hmax = maximum orifice diff pressure (e.g., 100 if hsrg is in percent of range)

Anti-Surge Flow Setpoint Calculation – Discharge Orifice

The term hsrg in equation 3 is at suction conditions. If the flow meter is in the discharge line, then hsrg must be adjusted to discharge conditions and the surge flow Fsrg calculated as follows:

ho = hsrg * (ρor / ρo) * (ρs / ρsr) (5)

Fsrg = Fmax * SQRT (ho / hmax) (6)

where:

ho = orifice differential pressure at discharge conditions

ρo = flowing density at actual orifice conditions

ρor = flowing density at reference orifice conditions

ρs = flowing density at actual suction conditions

ρsr = flowing density at reference suction conditions

Fmax = orifice flow range

For ideal gases, flowing density can be calculated as follows:

ρ = P * M / (R * T * Z) (7)

where:

P = absolute pressure

M = molecular weight

R = ideal gas constant

T = absolute temperature

Z = compressibility

Minimum Control Margin

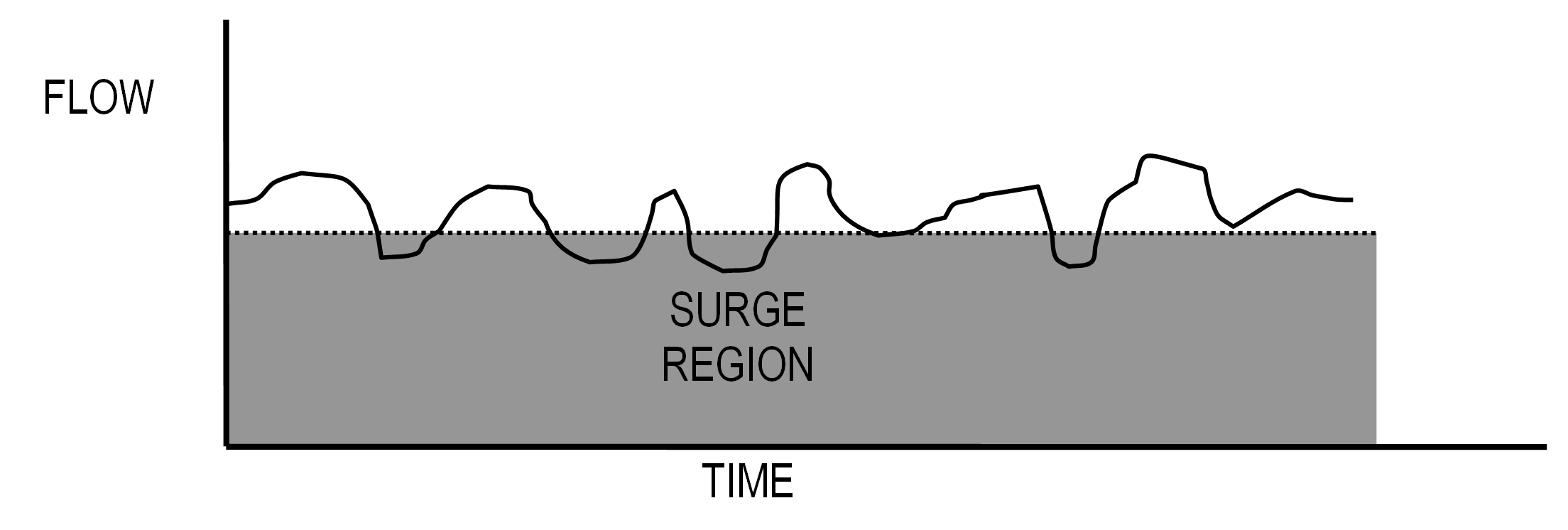

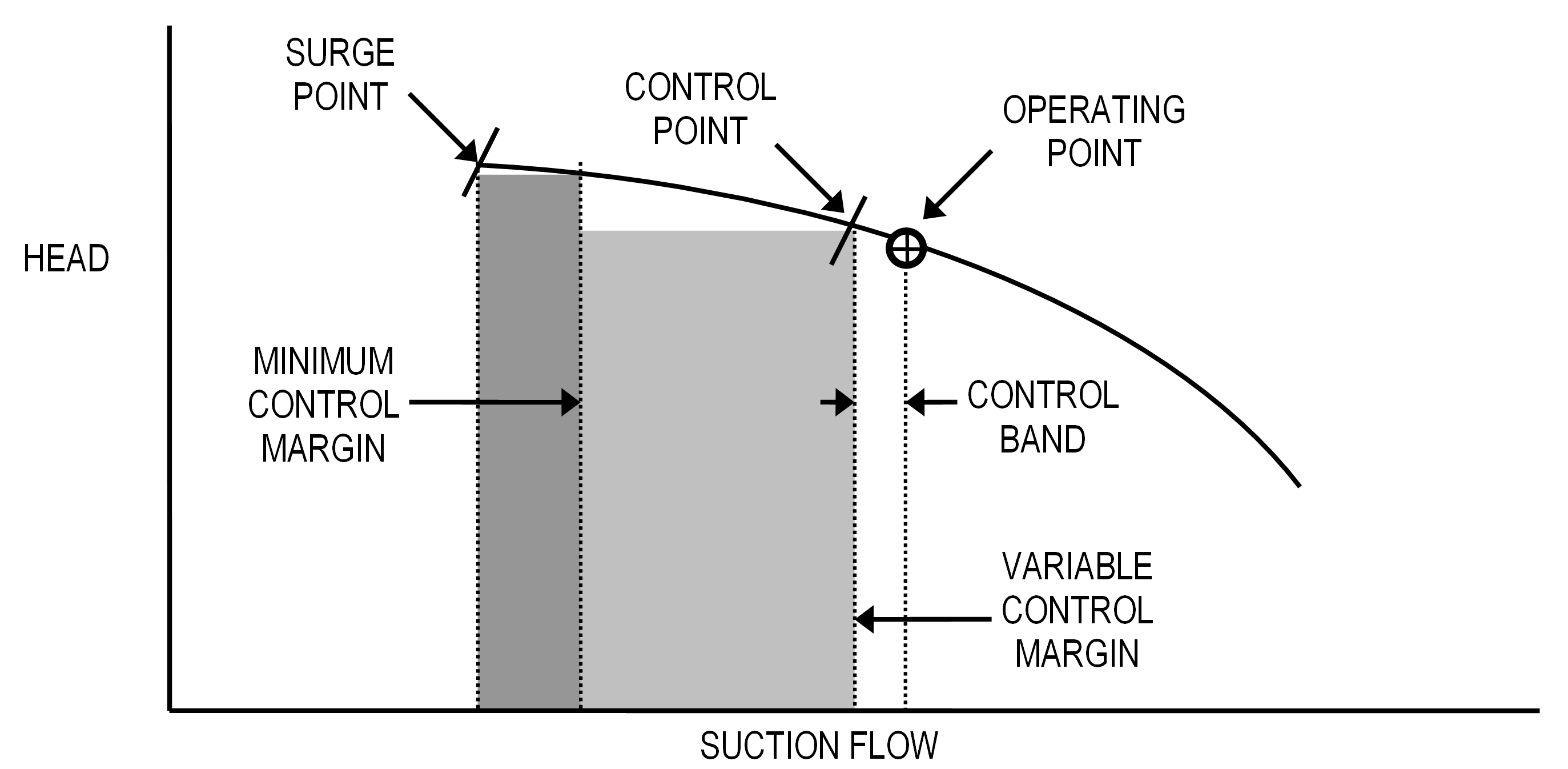

The anti-surge controller must always maintain the flow through the compressor above the surge point. However, if the controller attempts to control at the surge point, then minor fluctuations could cause the compressor to go into surge before the controller could take control action, as shown in Figure 2.

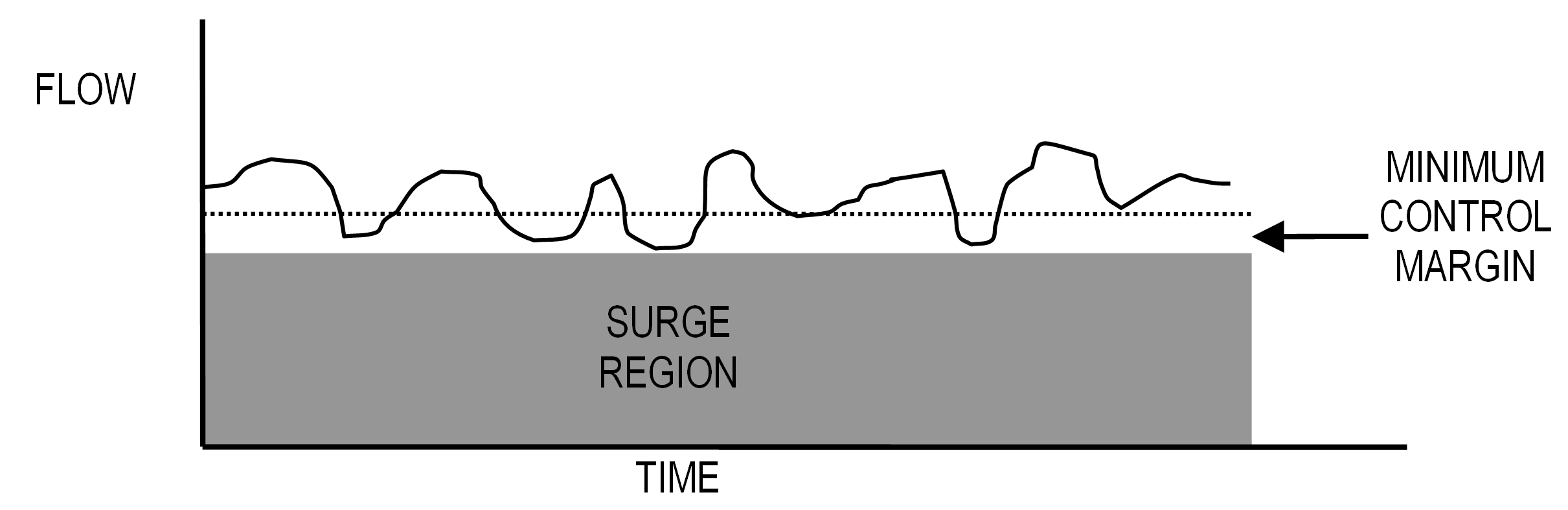

Therefore, a minimum control margin is added to the surge point. The margin ensures that the flow will be slightly above the surge point even during minor fluctuations, as shown in Figure 3.

Control Point Equation

The equation for calculating the control point is as follows:

Fctl = Fsrg * (1 + Km / 100) (8)

where:

Fctl = control point

Fsrg = surge flow

Km = minimum control margin in %.

Variable Control Margin

A variable control margin is added to the control point before it is stored to the setpoint of the anti-surge flow controller. The objective of the variable control margin is to provide additional protection against a sudden loss of flow. The variable margin provides the anti-surge controller with more time to open the recycle or blowoff valve before surge is reached.

Variable Control Margin Examples

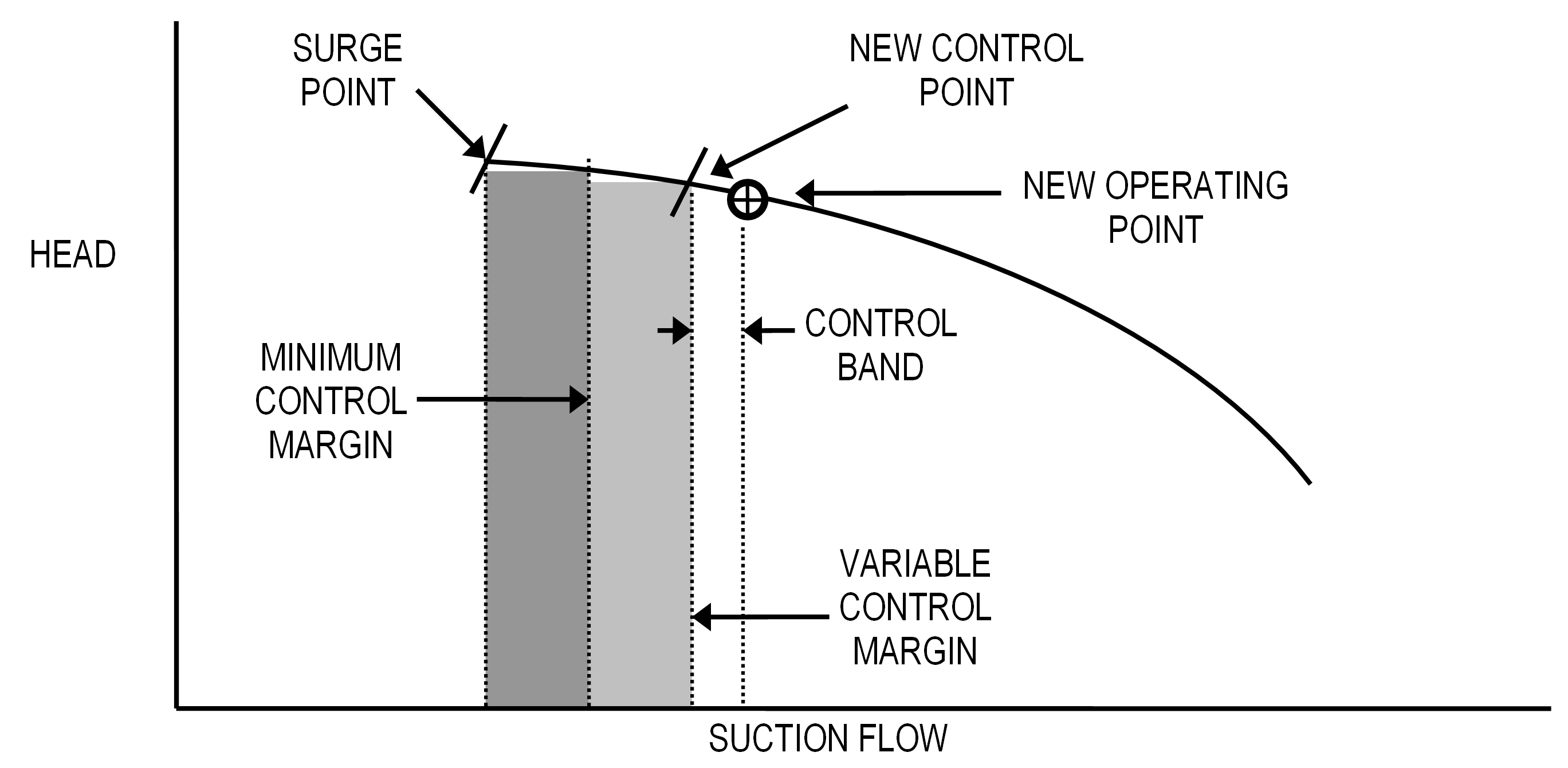

The variable control margin concept can be illustrated using a performance curve like Figure 1b. Figure 4 shows the compressor operating well above the minimum control margin. The anti-surge flow controller setpoint (control point) is set within an engineer-entered control band below the current operating point.

If the flow drops off and the anti-surge controller opens the recycle or blowoff valve, the variable control margin is ramped down at an engineer-entered rate until either the valve is closed, or the minimum control margin is reached. Figure 5 shows the variable margin re-established at a lower flow rate.

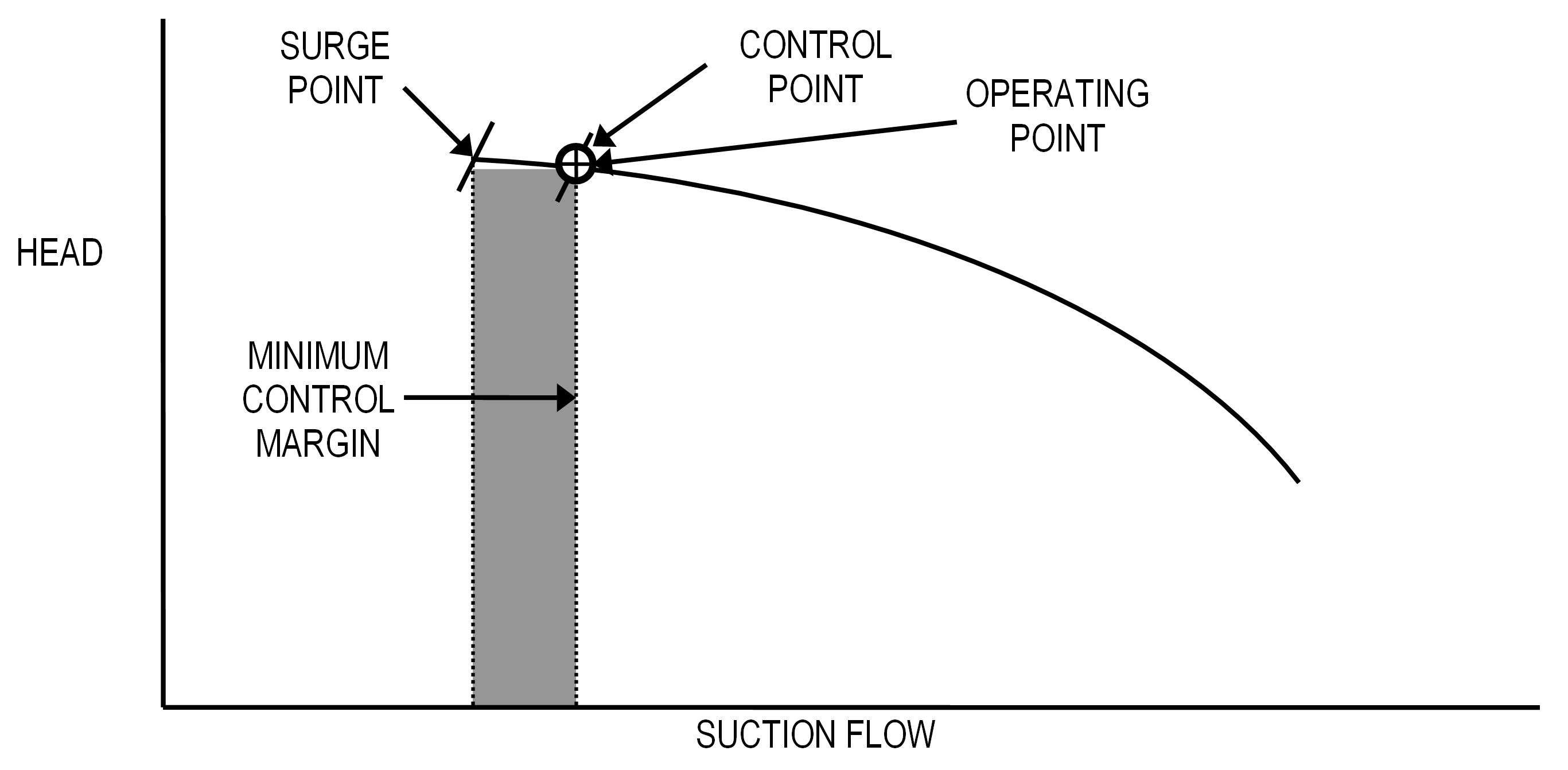

Figure 6 shows the compressor operating at the minimum margin. In this case, there is no variable margin because the operation is too close to the surge point.

Variable Margin Equations

The equations for variable control margin are as follows:

Fspt = Ffilt – Fband (9)

where:

Fspt = anti-surge flow controller RSP

Ffilt = anti-surge flow controller MEAS (filtered)

Fband = anti-surge flow control band

The anti-surge flow controller MEAS is filtered (Ffilt) to prevent short-term fluctuations from affecting the variable control margin calculation. The filtering algorithm is implemented as follows:

Ffilt = [Fold * Kfilt] + [Fmeas * (1 – Kfilt)] (10)

where:

Fmeas = anti-surge flow controller MEAS input

Fold = previous value of Ffilt

Kfilt = filter constant (0=no filter; 1=total filter)

Anti-Surge Flow Control

The previous sections describe how the setpoint is arrived at for the anti-surge controller. This controller is basically a flow controller that adjusts the anti-surge valve at a frequency of at least 500 ms, and in some applications 100 ms, to control the flow measurement at or above the setpoint. The controller includes several advanced control techniques, which are discussed next.

Adaptive Controller Tuning

The anti-surge flow controller tuning is automatically adjusted depending upon whether the flow is above or below the setpoint. Normal tuning is used when the flow is above setpoint. When the flow is below setpoint, the controller tuning is set faster to quickly return the flow to setpoint. How fast the tuning is set depends upon how far below setpoint the flow has fallen.

Adaptive Tuning Equations

The equations for adaptive tuning are as follows:

Padapt = Pnorm / Kadapt (11)

Iadapt = Inorm / Kadapt (12)

Kadapt = 2 ** {100 * [1 – (Fmeas / Fspt)] / Kdev} (13)

where:

Padapt = adapted PBAND used in anti-surge controller

Pnorm = PBAND setting for normal operation (above control point)

Iadapt = adapted INT used in anti-surge flow controller

Inorm = INT setting for normal operation (above control point)

Kadapt = adaptive tuning factor (limited to a minimum of 1.0)

Fmeas = anti-surge controller MEAS

Fspt = anti-surge controller SPT

Kdev = anti-surge controller negative deviation at which tuning constants are halved (% of SPT)

Asymmetrical Control Action

The adaptive tuning technique previously discussed can result in extremely rapid opening and closing of the recycle or blowoff valve. This is especially likely as the flow approaches surge because the flow input will become noisier.

To prevent this potential control instability, the SAS compressor anti-surge controls include asymmetrical control action. This feature allows the recycle or blowoff valve to open quickly to avoid surge, but close gradually to prevent upsetting other control functions.

Surge Line Violation

As the compressor operation approaches the surge line, the flow through the compressor can become erratic. If the flow reaches the surge line, then the control margin is automatically increased to push the control line further away from the surge line. An alarm can also be issued, if desired. The margin can increase only up to the maximum margin specified by the engineer.

The control margin can be set back to the original minimum control margin either automatically or manually. The automatic reset is based on elapsed time since the last event. The reset time is set by the engineer. The manual reset is via a button on the anti-surge control graphic display.

Frequent surge line violations are a sign that the minimum control margin is too close to the actual surge point. Therefore, the minimum control margin should be gradually increased until the violations become less frequent.

Input Checking

The SAS compressor control logic checks each input and takes appropriate action in the event of a bad value. The following inputs are checked:

- Anti-surge flow input

When a bad input is detected, the anti-surge controller input is set slightly above zero thus causing the anti-surge valve to go wide open.

- Pressures and Temperatures

The suction pressure, suction temperature, discharge pressure and discharge temperature are limited to minimum and maximum values. When a bad input is detected, these inputs are set to the safest possible setpoint for the anti-surge controller.

X-Y Plot

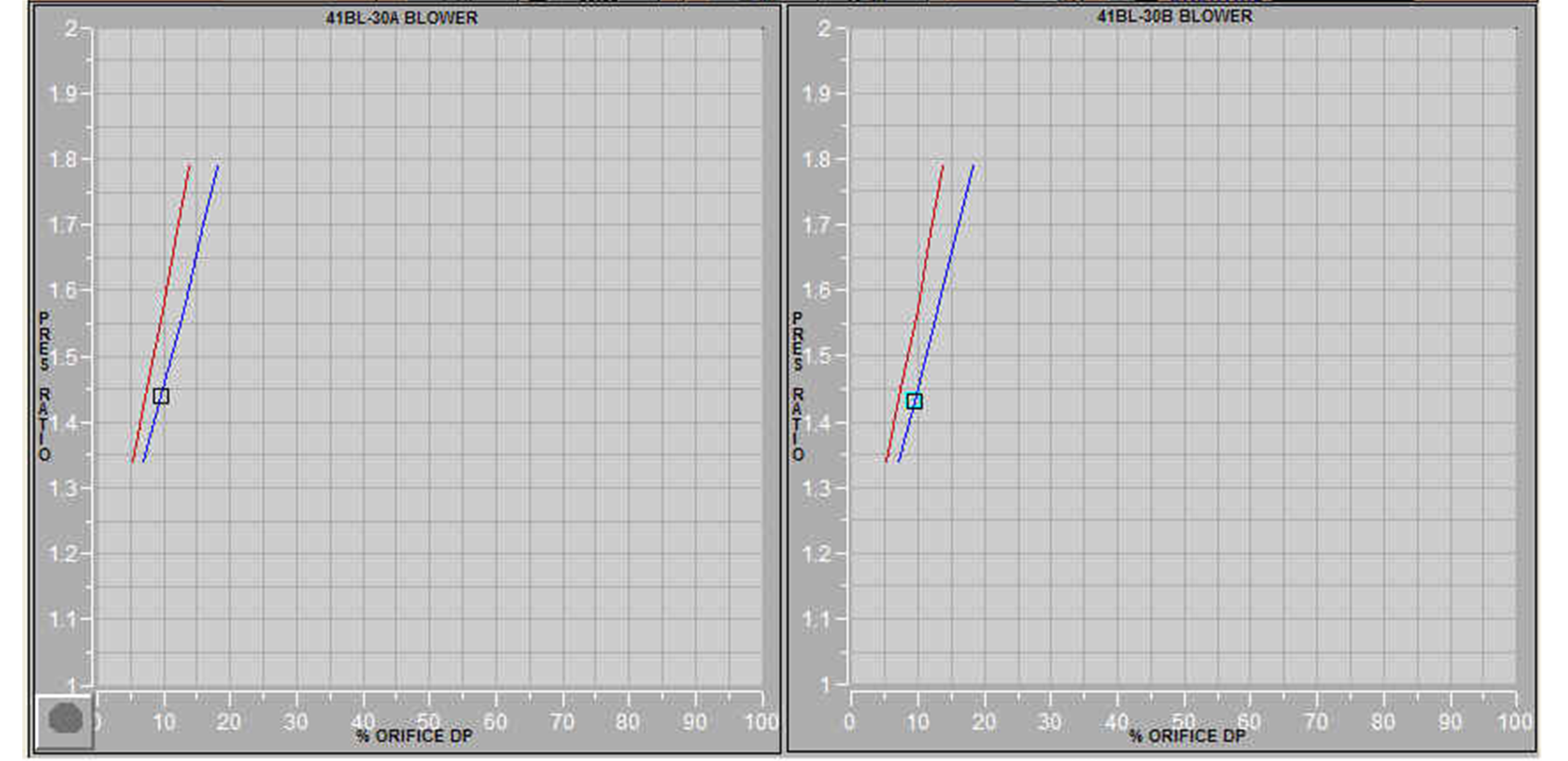

A plot of pressure ratio versus flow (% orifice dP) is typically included for each compressor. It can be called up from the process display by clicking the mouse on a button labeled XY PLOT. For dual parallel compressors, both plots can be configured to appear side-by-side, as shown in Figure 7.

The surge line appears in red, and the minimum control line appears in blue. The current operating point is shown as a black square. The operating point is continuously updated to reflect the current conditions. Previous positions of the operating point appear as light green squares.

DCS Implementation

The SAS compressor anti-surge controls are implemented via standard Foxboro I/A blocks. Each compressor has its own compound containing a similar set of blocks. An FCP270 can host the controls for at least seven compressors, but multiple compressors are typically distributed among several control processors. Therefore, the number of compressors in a single CP is seldom more than two.

DCS IMPLEMENTATION – INPUT BLOCKS

Anti-Surge Input Blocks

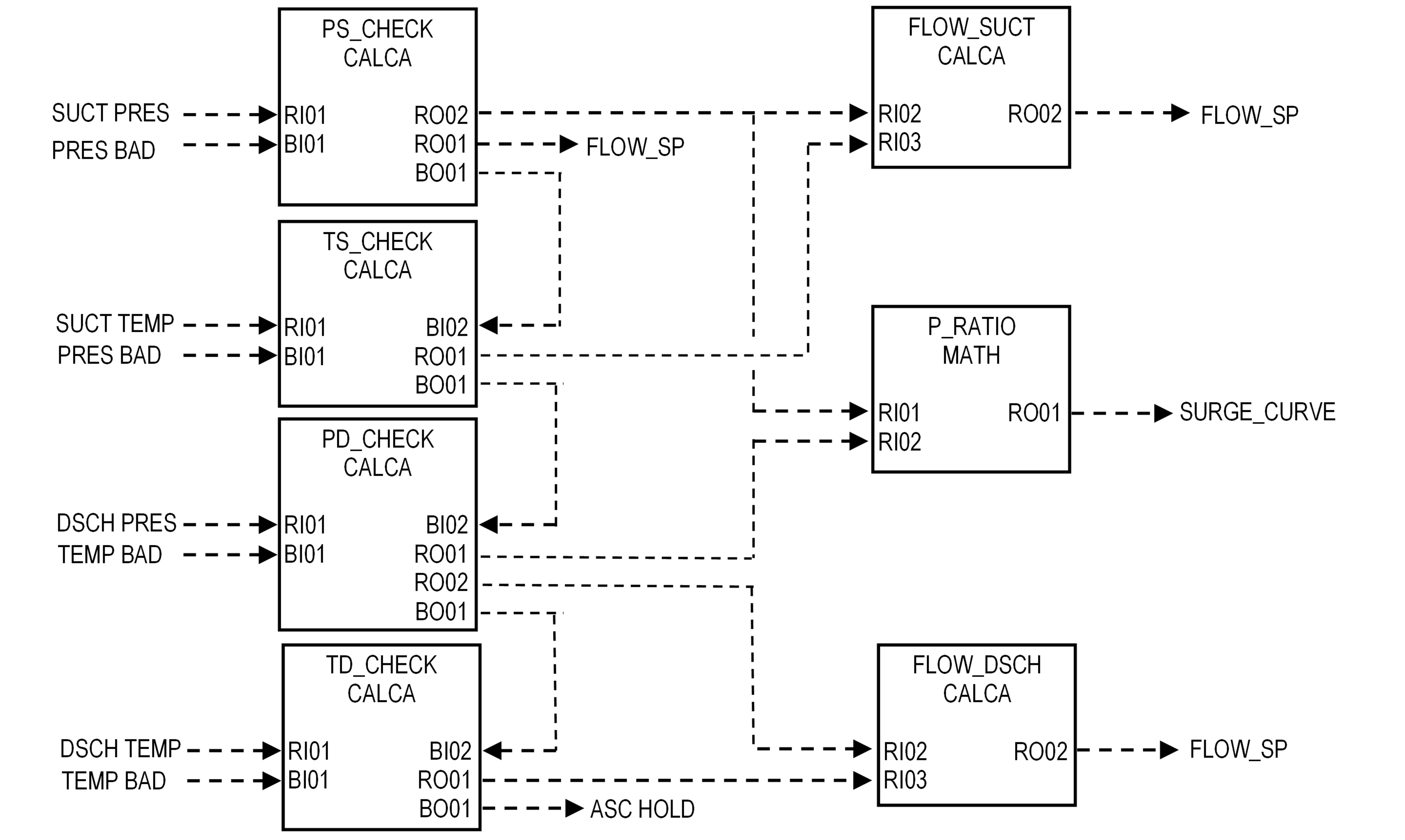

Figure 8 shows the block schematic for the input blocks in a typical compressor anti-surge control application (should be executed in this order):

- CALCA block for checking the suction pressure input (PS_CHECK).

- CALCA block for checking the suction temperature input (TS_CHECK).

- CALCA block for checking the discharge pressure input (PD_CHECK).

- CALCA block for checking the discharge temperature input (TD_CHECK).

- CALCA block for calculating pressure ratio (P_RATIO).

- CALCA block for calculating the suction flow compensation factor (FLOW_SUCT).

- CALCA block for calculating the discharge flow compensation factor (FLOW_DSCH).

Note: Blocks TD_CHECK and FLOW_DSCH are not required if the anti-surge flow orifice is in the suction.

Suction Pressure Input Check Block PS_CHECK

PS_CHECK is a CALCA block that checks the suction pressure input for bad input and for violation of maximum and minimum limits. If necessary, the block can also convert the input to absolute units (e.g., PSIG to PSIA). The following connections are required:

RI01 = Suction pressure

BI01 = Suction pressure bad input (lock to zero if bad status can be obtained from the RI01 input via the RDB command)

BI02 = Hold signal from another block (lock to zero if no other hold signal)

MA = :PS_CHECK.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

RI03 = Suction pressure minimum limit (same units as RI01)

RI04 = Suction pressure maximum limit (same units as RI01)

TIMINI = 3

M01 = Hold signal pulse time (sec)

M02 = Absolute conversion (0.0 if suction pressure is PSIA or 14.7 if PSIG)

M03 = Bad input signal delay on time (sec)

M04 = Bad input signal delay off time (sec)

The block generates the following outputs:

RO01 = Suction pressure in absolute units (RO04 substituted if input is bad)

RO02 = Suction pressure in absolute units (RO03 substituted if input is bad)

RO03 = Low limit (RI03) converted to absolute units

RO04 = High limit (RI04) converted to absolute units

BO01 = Anti-surge controller hold signal

BO02 = Flag denoting that input has been limited to the low limit

BO03 = Flag denoting that input has been limited to the high limit

BO04 = Bad input flag

BO05 = Bad input flag (delayed)

M11 = Suction pressure (RI01) converted to absolute units

Suction Pressure Input Check Block Steps

STEP01 = ADD RI03 M02 ;MIN INP + ABS

STEP02 = OUT RO03 ;ABS MIN INPUT

STEP03 = ADD RI04 M02 ;MAX INP + ABS

STEP04 = OUT RO04 ;ABS MAX INPUT

STEP05 = CLR BO02 ;MIN LIMIT FLAG

STEP06 = CLR BO03 ;MAX LIMIT FLAG

STEP07 = RBD RI01 ;BAD INPUT

STEP08 = OR BI01 ;BAD INPUT

STEP09 = OUT BO04 ;BAD FLAG

STEP10 = DON M03 ;FILTER OUT BLIPS

STEP11 = DOFF M04 ;DELAY GOING GOOD

STEP12 = OUT BO05 ;BAD FLAG DELAYED

STEP13 = IN BO04

STEP14 = BIF 21

STEP15 = IN BO05

STEP16 = BIF 36 ;FILTER OUT BLIPS

STEP17 = IN RO04 ;ABS MAX INPUT

STEP18 = OUT RO01 ;ABS INP (HI IF BAD)

STEP19 = IN RO03 ;ABS MIN INPUT

STEP20 = GTO 35

STEP21 = ADD RI01 M02 ;CONV TO ABS

STEP22 = OUT M11

STEP23 = SUB M11 RO04 ;CK MAX LIM

STEP24 = BIN 28

STEP25 = SET BO03 ;MAX LIM FLAG

STEP26 = IN RO04

STEP27 = GTO 34

STEP28 = SUB M11 RO03 ;CK MIN LIM

STEP29 = BIP 33

STEP30 = SET BO02 ;MIN LIM FLAG

STEP31 = IN RO03

STEP32 = GTO 34

STEP33 = IN M11

STEP34 = OUT RO01 ;ABS INP (HI IF BAD)

STEP35 = OUT RO02 ;ABS INP (LO IF BAD)

STEP36 = CST

STEP37 = IN BO05 ;INP BECOMING BAD

STEP38 = OSP M01

STEP39 = IN ~BO05 ;INP BECOMING GOOD

STEP40 = OSP M01

STEP41 = IN BI02 ;HOLD SIG FM OTHER BLK

STEP42 = OR 3

STEP43 = OUT BO01 ;ASC HOLD SIGNAL

STEP44 = END

Suction Pressure Input Check Block Logic Details

Steps 1-4: Convert limits to absolute units and store minimum limit to RO03 and maximum limit to RO04.

Steps 5-6: Clear limit violation flags BO02 and BO03. These flags will be set in steps 25 and 30 if the limits are violated.

Steps 7-9: Determine if the input (RI01 or BI01) is bad and store the result to BO04.

Steps 10-12: Perform a delay on and a delay off and store the result to BO05. The purpose is to filter out blips in the bad status that would cause a needless bump in the controls.

Steps 13-14: If the bad flag BO04 is off, then go to step 21.

Steps 15-16: If the delayed bad flag BO05 is off, then go to step 36.

Steps 17-20: The delayed bad flag BO05 is on, so store the maximum limit (RO04) to RO01 and go to step 35 to store the minimum limit (RO03) to RO01.

Steps 21-22: Convert the input to absolute units by adding M02 and store the result to M11.

Steps 23-27: If the input (M11) is above the maximum limit (RO04), then set the limit violation flag BO03 and go to step 34 to store the maximum limit to both RO01 and RO02.

Steps 28-32: If the input (M11) is below the minimum limit (RO03), then set the limit violation flag BO02 and go to step 34 to store the minimum limit to both RO01 and RO02.

Steps 33-35: The input (M11) is within the limits (RO03), so store it to both RO01 and RO02.

Steps 37-43: Generate an on pulse when the delayed bad flag (BO05) has just become bad or when it has just become good. OR the result with BI02 and store to BO01.

Suction Temperature Input Check Block TS_CHECK

TS_CHECK is a CALCA block that checks the suction temperature input for bad input and for violation of maximum and minimum limits. The block also converts the input to absolute units (e.g., DEGF to DEGR). The following connections are required:

RI01 = Suction temperature

BI01 = Suction temperature bad input (lock to zero if bad status can be obtained from the RI01 input via the RDB command)

BI02 = :PS_CHECK.BO01 (hold signal)

MA = :TS_CHECK.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

RI03 = Suction temperature minimum limit (same units as RI01)

RI04 = Suction temperature maximum limit (same units as RI01)

TIMINI = 3

M01 = Hold signal pulse time (sec)

M02 = Absolute conversion (460.0)

M03 = Bad input signal delay on time (sec)

M04 = Bad input signal delay off time (sec)

The block generates the following outputs:

RO01 = Suction temperature in absolute units (RO04 substituted if input is bad)

RO02 = Suction temperature in absolute units (RO03 substituted if input is bad)

RO03 = Low limit (RI03) converted to absolute units

RO04 = High limit (RI04) converted to absolute units

BO01 = Anti-surge controller hold signal

BO02 = Flag denoting that input has been limited to the low limit

BO03 = Flag denoting that input has been limited to the high limit

BO04 = Bad input flag

BO05 = Bad input flag (delayed)

M11 = Suction temperature (RI01) converted to absolute units

Suction Temperature Input Check Block Steps

The steps for block TS_CHECK are identical to those for PS_CHECK.

Discharge Pressure Input Check Block PD_CHECK

PD_CHECK is a CALCA block that checks the discharge pressure input for bad input and for violation of maximum and minimum limits. If necessary, the block can also convert the input to absolute units (e.g., PSIG to PSIA). The following connections are required:

RI01 = Discharge pressure

BI01 = Discharge pressure bad input (lock to zero if bad status can be obtained from the RI01 input via the RDB command)

BI02 = :TS_CHECK.BO01 (hold signal)

MA = :PD_CHECK.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

RI03 = Discharge pressure minimum limit (same units as RI01)

RI04 = Discharge pressure maximum limit (same units as RI01)

TIMINI = 3

M01 = Hold signal pulse time (sec)

M02 = Absolute conversion (0.0 if discharge pressure is PSIA or 14.7 if PSIG)

M03 = Bad input signal delay on time (sec)

M04 = Bad input signal delay off time (sec)

The block generates the following outputs:

RO01 = Discharge pressure in absolute units (RO04 substituted if input is bad)

RO02 = Discharge pressure in absolute units (RO03 substituted if input is bad)

RO03 = Low limit (RI03) converted to absolute units

RO04 = High limit (RI04) converted to absolute units

BO01 = Anti-surge controller hold signal

BO02 = Flag denoting that input has been limited to the low limit

BO03 = Flag denoting that input has been limited to the high limit

BO04 = Bad input flag

BO05 = Bad input flag (delayed)

M11 = Discharge pressure (RI01) converted to absolute units

Discharge Pressure Input Check Block Steps

The steps for block PD_CHECK are identical to those for PS_CHECK.

Discharge Temperature Input Check Block TD_CHECK

TD_CHECK is a CALCA block that checks the suction temperature input for bad input and for violation of maximum and minimum limits. The block also converts the input to absolute units (e.g., DEGF to DEGR). The following connections are required:

RI01 = Discharge temperature

BI01 = Discharge temperature bad input (lock to zero if bad status can be obtained from the RI01 input via the RDB command)

BI02 = :PD_CHECK.BO01 (hold signal)

MA = :TD_CHECK.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

RI03 = Discharge temperature minimum limit (same units as RI01)

RI04 = Discharge temperature maximum limit (same units as RI01)

TIMINI = 3

M01 = Hold signal pulse time (sec)

M02 = Absolute conversion (460.0)

M03 = Bad input signal delay on time (sec)

M04 = Bad input signal delay off time (sec)

The block generates the following outputs:

RO01 = Discharge temperature in absolute units (RO04 substituted if input is bad)

RO02 = Discharge temperature in absolute units (RO03 substituted if input is bad)

RO03 = Low limit (RI03) converted to absolute units

RO04 = High limit (RI04) converted to absolute units

BO01 = Anti-surge controller hold signal

BO02 = Flag denoting that input has been limited to the low limit

BO03 = Flag denoting that input has been limited to the high limit

BO04 = Bad input flag

BO05 = Bad input flag (delayed)

M11 = Discharge temperature (RI01) converted to absolute units

Discharge Temperature Input Check Block Steps

The steps for block TD_CHECK are identical to those for PS_CHECK.

Suction Flow Calculation Block FLOW_SUCT

FLOW_SUCT is a CALCA block that is used to compensate flow for changes in pressure and temperature. It is also used in the anti-surge application to calculate the gas density at suction conditions (ρs) using equation 7. The block also calculates the gas density at reference conditions (ρsr) and the flow compensation factor SQRT(ρs/ρsr). The following connections are required:

RI01 = Suction flow (not needed for anti-surge – enter 1.0)

RI02 = :PS_CHECK.RO02 (absolute suction pressure)

RI03 = :TS_CHECK.RO01 (absolute suction temperature)

RI08 = Other mass flow (not needed for anti-surge – enter 0.0)

MA = :FLOW_SUCT.MA.1 (lock to auto)

BI01 = Bad flow signal (not needed for anti-surge – lock to 0)

BI02 = Bad pressure signal (not needed for anti-surge – lock to 0)

BI03 = Bad temperature signal (not needed for anti-surge – lock to 0)

BI04 = Bad other mass flow signal (not needed for anti-surge – lock to 0)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

RI04 = Gas molecular weight M

RI05 = Gas compressibility factor Z

RI06 = Minimum compensation factor

RI07 = Maximum compensation factor

TIMINI = 3

M02 = 0.0

M03 = 0.0

M11 = Ideal gas constant R (10.73)

M12 = Reference pressure absolute

M13 = Reference temperature absolute

M14 = Reference gas molecular weight

M15 = Reference gas compressibility factor

The block generates the following outputs:

RO01 = Compensated flow

RO02 = Flow compensation factor

RO03 = Gas density at suction conditions

RO04 = Gas density at suction reference conditions

BO01 = Bad compensated flow signal

M18 = Suction pressure (RI02) converted to absolute units

M19 = Suction temperature (RI03) converted to absolute units

M20 = Flow fraction of range

Suction Flow Calculation Block Steps

STEP01 = MUL M12 M14 ;PREF * MREF

STEP02 = MUL M13 M15 ;TREF * ZREF

STEP03 = MUL M11 ;R

STEP04 = DIV

STEP05 = OUT RO04 ;REF DENSITY

STEP06 = CST

STEP07 = IN BI02 ;BAD PRES

STEP08 = BIT 11

STEP09 = ADD RI02 M02 ;ABS PRES

STEP10 = GTO 12

STEP11 = IN M12 ;PREF

STEP12 = OUT M18 ;ABS PRES

STEP13 = IN BI03 ;BAD TEMP

STEP14 = BIT 17

STEP15 = ADD RI03 M03 ;ABS TEMP

STEP16 = GTO 18

STEP17 = IN M13 ;TREF

STEP18 = OUT M19 ;ABS TEMP

STEP19 = CST

STEP20 = MUL M18 RI04 ;P * MW

STEP21 = MUL M19 RI05 ;T * Z

STEP22 = MUL M11 ;R

STEP23 = DIV

STEP24 = OUT RO03 ;FLOWING DENSITY

STEP25 = CST

STEP26 = DIV RO03 RO04 ;FLOW DENS / REF DENS

STEP27 = SQRT

STEP28 = IN RI06 ;MIN COMP FACTOR

STEP29 = MAX 2

STEP30 = IN RI07 ;MAX COMP FACTOR

STEP31 = MIN 2

STEP32 = OUT RO02 ;COMP FACTOR

STEP33 = CST

STEP34 = MUL RI01 RO02 ;FLOW SQRT

STEP35 = ADD RI08 ;OTHER FLOW

STEP36 = IN 0

STEP37 = MAX 2

STEP38 = OUT RO01 ;TOTAL MASS FLOW

STEP39 = CST

STEP40 = OR BI01 BI04 ;BAD FLOW

STEP41 = BIT 45

STEP42 = CLR BO01 ;BAD FLOW FLAG

STEP43 = CBD RO01 ;FLOW GOOD

STEP44 = EXIT

STEP45 = SET BO01 ;BAD FLOW FLAG

STEP46 = SBD RO01 ;FLOW BAD

STEP47 = END

Suction Flow Calculation Block Logic Details

Steps 1-5: Calculate the gas reference density using equation 7 and store the result to RO04.

Steps 7-12: If the pressure input is bad, then store the reference pressure to M18. Otherwise, convert the pressure input to absolute (unless it is already absolute) and store to M18.

Steps 13-18: If the temperature input is bad, then store the reference temperature to M19. Otherwise, convert the temperature input to absolute (unless it is already absolute) and store to M19.

Steps 20-24: Calculate the gas flowing density using equation 7 and store the result to RO03.

Steps 26-32: Calculate the flow compensation factor, limit it to the minimum (RI06) and the maximum (RI07), and store the result to RO02.

Steps 34-38: Calculate the compensated flow, add the other mass flow input (RI08), limit the result to zero, and store it to RO01.

Steps 40-46: If either flow input is bad (BI01 or BI04), then set the bad flow flag and mark the compensated flow (RO01) as bad. Otherwise, clear the bad flow flag and mark the compensated flow (RO01) as good.

Discharge Flow Calculation Block FLOW_DSCH

FLOW_DSCH is a CALCA block that is used to compensate flow for changes in pressure and temperature. It is also used in the anti-surge application to calculate the gas density at discharge conditions (ρo) using equation 7. The block also calculates the gas density at reference conditions (ρor) and the flow compensation factor SQRT(ρo/ρor). The following connections are required:

RI01 = Discharge flow (not needed for anti-surge – enter 1.0)

RI02 = :PD_CHECK.RO02 (absolute discharge pressure)

RI03 = :TD_CHECK.RO01 (absolute discharge temperature)

RI08 = Other mass flow (not needed for anti-surge – enter 0.0)

MA = :FLOW_DSCH.MA.1 (lock to auto)

BI01 = Bad flow signal (not needed for anti-surge – lock to 0)

BI02 = Bad pressure signal (not needed for anti-surge – lock to 0)

BI03 = Bad temperature signal (not needed for anti-surge – lock to 0)

BI04 = Bad other mass flow signal (not needed for anti-surge – lock to 0)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

RI04 = Gas molecular weight M

RI05 = Gas compressibility factor Z

RI06 = Minimum compensation factor

RI07 = Maximum compensation factor

TIMINI = 3

M02 = 0.0

M03 = 0.0

M11 = Ideal gas constant R (10.73)

M12 = Reference pressure absolute

M13 = Reference temperature absolute

M14 = Reference gas molecular weight

M15 = Reference gas compressibility factor

The block generates the following outputs:

RO01 = Compensated flow

RO02 = Flow compensation factor

RO03 = Gas density at discharge conditions

RO04 = Gas density at discharge reference conditions

BO01 = Bad compensated flow signal

M18 = Discharge pressure (RI02) converted to absolute units

M19 = Discharge temperature (RI03) converted to absolute units

M20 = Flow fraction of range

Discharge Flow Calculation Block Steps

The steps for block FLOW_DSCH are identical to those for FLOW_SUCT.

Pressure Ratio Block P_RATIO

P_RATIO is a MATH block that calculates the pressure ratio via equation 1. The following connections are required:

RI01 = Absolute suction pressure (e.g., PSIA)

RI02 = Absolute discharge pressure (e.g., PSIA)

MA = :P_RATIO.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

TIMINI = 3

M01 = Minimum suction pressure to prevent divide by zero (e.g., 0.1)

The block generates the following outputs:

RO01 = Pressure ratio

Pressure Ratio Block Steps

STEP01 = IN RI02 ;DISCH PRES ABS

STEP02 = IN RI01 ;SUCTION PRES ABS

STEP03 = IN M01 ;PREVENT DIV BY ZERO

STEP04 = MAX 2

STEP05 = DIV

STEP06 = OUT RO01 ;PRES RATIO

STEP07 = END

DCS IMPLEMENTATION – SURGE CURVE BLOCKS

Surge Curve Blocks

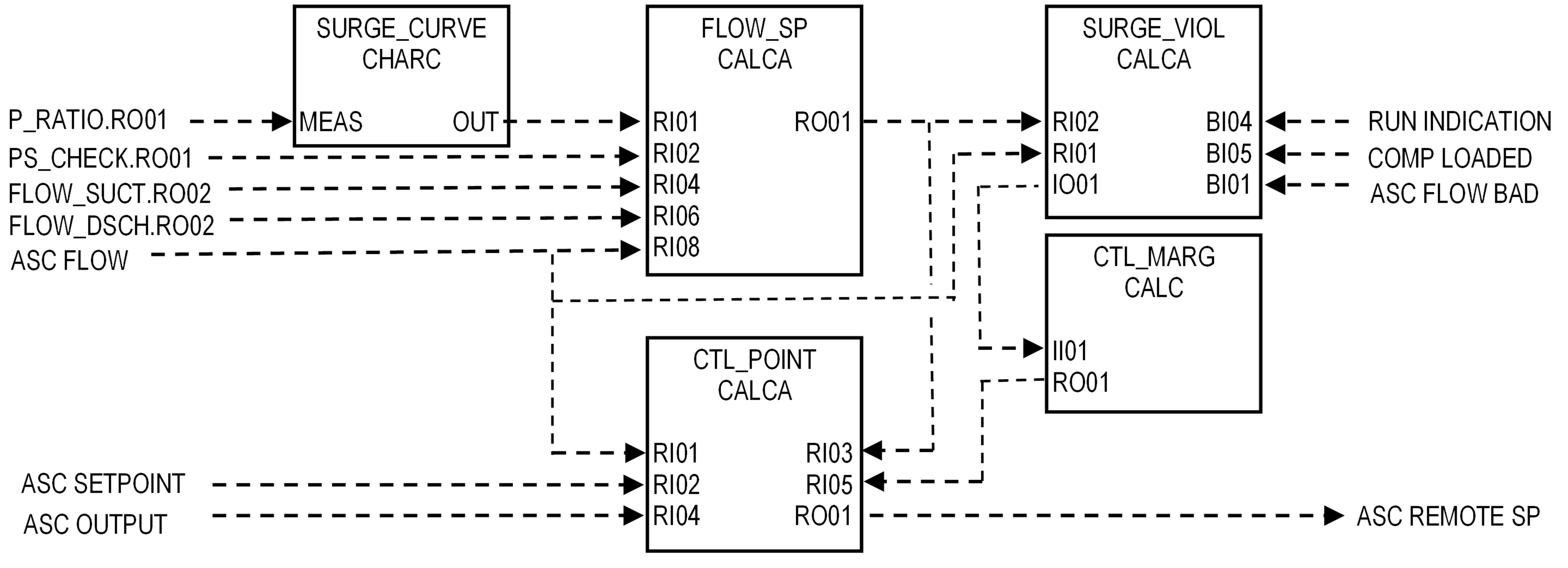

Figure 9 shows the block schematic for the blocks that implement the surge curve in a typical compressor anti-surge control application (should be executed in this order):

- CHARC block containing the surge curve coordinate pairs (SURGE_CURVE).

- CALCA block that converts the surge point to flow units (FLOW_SP).

- CALCA block for surge line violation (SURGE_VIOL).

- CALC block for determining the control margin (CTL_MARG).

CALCA block for determining the final control point (CTL_POINT).

Surge Curve Block SURGE_CURVE

SURGE_CURVE is a CHARC block that contains the surge curve. The points on the curve are entered as x-y pairs, where x is the pressure ratio Rc and y is the corresponding orifice differential pressure hc.

The following connections are required:

MEAS = :P_RATIO.RO01

MA = :SURGE_CURVE.MA.1 (lock to auto)

The following parameters must be set accordingly:

HSCO1 = Highest value of hc allowed

LSCO1 = Lowest value of hc allowed

ENDP = Number of points entered from performance curve

X_1 = Lowest pressure ratio

Y_1 = hc at X_1 pressure ratio

X_2 = Next higher pressure ratio

Y_2 = hc at X_2 pressure ratio

: :

X_n = Highest pressure ratio (n = value in ENDP)

Y_n = hc at X_n pressure ratio

Usually, only five points are required to define the surge curve.

Surge Point Conversion Block FLOW_SP

FLOW_SP is a CALCA block that converts the surge point from hc to flow units using equation 3. The following connections are required:

RI01 = :SURGE_CURVE.OUT (surge point in hc)

RI02 = :PS_CHECK.RO01 (suction pressure)

RI04 = :FLOW_SUCT.RO02 (flow compensation factor at suction conditions)

RI06 = :FLOW_DSCH.RO02 (flow compensation factor at orifice conditions. Note: If flow orifice is in suction, then use FLOW_SUCT.RO02)

RI08 = Anti-surge flow measurement

MA = :FLOW_SP.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

RI03 = Suction reference pressure (Psr in equation 3)

RI05 = Anti-surge flow range

TIMINI = 3

M01 = Minimum flow (prevent divide by zero)

M02 = Maximum hc (100.0 if %hc)

M03 = Absolute conversion (should be 0.0 because suction pressure is already absolute)

M04 = Constant 100.0

The block generates the following outputs:

RO01 = Surge point in flow units

RO02 = Percent surge for graphics

RO03 = hc calculation factor

RO04 = Current hc

M18 = Surge curve hsrg

Surge Point Conversion Block Steps

STEP01 = IN RI03 ;SUCT REF PRES

STEP02 = ADD RI02 M03 ;ABS PRESSURE

STEP03 = DIV

STEP04 = OUT RO03 ;REF/ACTUAL PRES

STEP05 = CST

STEP06 = DIV RI01 RO03 ;SURGE CURV %HC

STEP07 = OUT M18 ;SURGE CURVE %HS

STEP08 = DIV M02 ;MAX H

STEP09 = SQRT

STEP10 = DIV RI04 RI06 ;SUCT / ORIFICE COMP

STEP11 = MUL RI05 ;MAX FLOW

STEP12 = MUL 2

STEP13 = OUT RO01 ;ASC TGT FLOW

STEP14 = IN RI08 ;CURR FLOW

STEP15 = IN RO01 ;SURGE FLOW

STEP16 = IN M01 ;PROTECT DIV BY ZERO

STEP17 = MAX 2

STEP18 = DIV

STEP19 = MUL M04 ;100.0

STEP20 = SUB M04

STEP21 = OUT RO02 ;% SURGE

STEP22 = CST

STEP23 = DIV RI08 RI05 ;CURR FLOW/MAX FLOW

STEP24 = DIV RI08 RI05 ;SQUARED

STEP25 = DIV RI06 RI04 ;ORIFICE/SUCT COMP

STEP26 = DIV RI06 RI04 ;SQUARED

STEP27 = MUL 4

STEP28 = MUL M02 ;MAX H

STEP29 = MUL RO03 ;HC CALC FACTOR

STEP30 = OUT RO04 ;SUCTION %HC

STEP31 = END

Surge Point Conversion Block Logic Details

Steps 1-7: Calculate suction surge flow hsrg using equation 3 and store to M18.

Steps 8-13: Calculate the suction flow Fmax using equation 5 and 6 and store to RO01.

Steps 14-21: Calculate the current percent surge and store the result to RO02.

Steps 23-30: Calculate the current hc and store the result to RO04.

Surge Violation Block SURGE_VIOL

SURGE_VIOL is a CALCA block that determines when the current flow is violating the surge point. If so, it alerts the control margin block to increase the margin. The following connections are required:

RI01 = Anti-surge flow measurement

RI02 = :FLOW_SP.RO01 (surge point in flow units)

BI01 = Anti-surge flow measurement bad status

BI04 = Compressor run indication

BI05 = Compressor loaded indication

MA = :SURGE_VIOL.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

RI03 = Surge event duration (sec)

RI04 = Surge event timer reset time (hours)

RI05 = Allowable flow deviation below surge point (flow units)

BI02 = Surge event timer manual reset

TIMINI = 3

M01 = Constant 3600.0

M02 = Execution frequency (sec)

M04 = Surge event manual reset OSP time (sec)

The block generates the following outputs:

RO03 = Surge event timer (hours)

BO01 = Surge event alarm

BO02 = Surge event flag

BO03 = Reinitialization flag

BO04 = Manual reset flag

IO01 = Surge event counter to CTL_MARG.II01

M03 = Surge event duration (stored from RI03)

Surge Violation Block Steps

STEP01 = CLR BO02 ;SURGE EVENT FLAG

STEP02 = IN RI03 ;EVENT DURATION

STEP03 = OUT M03

STEP04 = IN BI02 ;MAN RESET

STEP05 = OSP M04

STEP06 = OUT BO04 ;MAN RESET FLAG

STEP07 = RCL BI02

STEP08 = BIF 11

STEP09 = CLR IO01 ;SURGE EVENT CNTR

STEP10 = CLR RO03 ;TIMER

STEP11 = AND BI04 BI05 ;RUNNING & LOADED?

STEP12 = BIF 15

STEP13 = IN BI01 ;BAD FLOW

STEP14 = BIF 17

STEP15 = SET BO03 ;RE-INIT FLAG

STEP16 = GTO 47

STEP17 = BII 38

STEP18 = CST

STEP19 = SUB RI04 RO03 ;RESET TIME – TIMER

STEP20 = BIP 23

STEP21 = DEC IO01 ;EVENT CNTR

STEP22 = CLR RO03 ;TIMER

STEP23 = CST

STEP24 = IN BO03 ;RE-INIT FLAG

STEP25 = BIT 38

STEP26 = CST

STEP27 = SUB RI01 RI02 ;CFLOW – SURGE PT

STEP28 = BIP 39

STEP29 = CHS

STEP30 = SUB RI05 ;EXPECTED NOISE

STEP31 = BIN 39

STEP32 = IN BO01 ;SURGE EVENT IN PROG

STEP33 = BIT 39

STEP34 = SET BO02 ;SURGE EVENT FLAG

STEP35 = INC IO01 ;EVENT CNTR

STEP36 = CLR RO03 ;TIMER

STEP37 = CST

STEP38 = CLR BO03 ;RE-INIT FLAG

STEP39 = NOP

STEP40 = NOP

STEP41 = NOP

STEP42 = IN IO01 ;EVENT CNTR

STEP43 = BIZ 46

STEP44 = DIV M02 M01 ;EXEC FREQ / 3600

STEP45 = ADD RO03 ;TIMER

STEP46 = OUT RO03

STEP47 = IN BO02 ;SURGE EVENT FLAG

STEP48 = OSP M03

STEP49 = OUT BO01 ;SURGE EVENT ALARM

STEP50 = END

Surge Violation Block Logic Details

Steps 1-3: Initialize surge event flag BO02 and store the event duration time RI03 to M03 for use in setting the surge event alarm.

Steps 4-6: If the manual reset is on (BI02), then generate a one-shot pulse to denote that the manual reset has occurred and store to BO04.

Steps 7-10: Read and clear BI02. If BI02 is on, then clear the surge event counter IO01 and timer RO03.

Steps 11-16: If compressor is not running or not fully loaded, or anti-surge flow is bad, then set re-initialization flag BO03 and go to step 47.

Step 17: If this is the block initialization pass (BII), go to step 38.

Steps 19-22: If the surge event timer RO03 exceeds the timer reset time RI04, then decrement the surge event counter IO01 and clear the surge event timer RO03.

Steps 24-25: If the re-initialization flag BO03 is set, then go to step 38.

Steps 27-28: If the anti-surge flow is at or above the surge point, then go to step 39.

Steps 29-31: If the anti-surge flow is below the surge point, but by no more than RI05, then go to step 39.

Steps 32-36: If a surge event is in progress (BO01 = 1), then go to step 39. Otherwise, set the surge event flag BO02 on, increment the surge event counter IO01, and clear the surge event timer RO03.

Step 38: Clear the re-initialization flag BO03.

Steps 39-46: If the surge event counter IO01 is zero, then zero the surge event timer RO03 by going to step 46. Otherwise, increase the surge event timer RO03 by the execution frequency converted to hours.

Steps 47-49: Perform a one-shot pulse for M03 seconds based on the surge event flag BO02 and store the result to the surge event in progress flag BO01. The duration of the surge event is in RI03, which was stored into M03 in step 3 above.

Control Margin Block CTL_MARG

CTL_MARG is a CALC block that determines the desired control margin above the surge point. The following connections are required:

II01 = :SURGE_VIOL.IO01 (surge violation counter)

MA = :CTL_MARG.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

RI01 = Minimum control margin (%)

HSCI1 = Highest allowed entry for RI01

LSCI1 = Lowest allowed entry for RI01

RI02 = Maximum control margin (%)

HSCI2 = Highest allowed entry for RI02

LSCI2 = Lowest allowed entry for RI02

RI03 = Margin increase for each surge point violation (%)

HSCI3 = Highest allowed entry for RI03

LSCI3 = Lowest allowed entry for RI03

RI05 = Margin ramp-down rate (%/execution)

HSCI5 = Highest allowed entry for RI05

LSCI5 = Lowest allowed entry for RI05 (should be > 0)

BI02 = Margin increase timer manual reset

TIMINI = 3

M01 = Constant 3600.0

M02 = Execution frequency (sec)

M03 = Margin increase alarm OSP time (sec)

M05 = Constant -1.0

HSCO1 = Highest allowed control margin RO01

LSCO1 = Lowest allowed control margin RO01 (must be < 0 for surge test)

HSCO2 = Highest allowed target control margin RO02

LSCO2 = Lowest allowed target control margin RO02 (must be < 0 for surge test)

HSCO3 = Highest allowed timer value RO03 (must be at least 99999)

LSCO4 = Lowest allowed margin change RO03 (must be -100.0)

The block generates the following outputs:

RO01 = Current control margin to CTL_POINT.RI03

RO02 = Control margin target

RO03 = Margin increase timer (hours)

RO04 = Margin change required this execution (%)

BO01 = Margin increase alarm

BO02 = Margin increase flag

IO01 = Margin increase counter

IO02 = Previous surge event counter from block SURGE_VIOL

Control Margin Block Steps

STEP01 = IN II01 ;EVENT CNTR FM SRG_VIOL

STEP02 = MUL RI03 ;INCR MARG SRG VIOL

STEP03 = NOP

STEP04 = NOP

STEP05 = NOP

STEP06 = ADD RI01 ;MIN MARGIN

STEP07 = IN RI02 ;MAX MARGIN

STEP08 = MIN 2

STEP09 = OUT RO02 ;TGT CNTL MARG

STEP10 = SUB RO01 ;CURR CTL MARG

STEP11 = BIP 15

STEP12 = IN RI05 ;RAMP DN RATE

STEP13 = MUL M05 ;-1.0

STEP14 = MAX 2

STEP15 = OUT RO04 ;MARG CHNG REQD

STEP16 = ADD RO01 ;CURR CTL MARG

STEP17 = OUT RO01 ;NEW CTL MARG

STEP18 = CST

STEP19 = CLR BO02 ;MARG INCR FLAG

STEP20 = RCL BI02 ;TIMER MAN RESET

STEP21 = BIF 24

STEP22 = CLR IO01 ;MARG INCR CNTR

STEP23 = CLR RO03 ;TIMER

STEP24 = BII 44

STEP25 = IN IO02 ;PREV SRG VIOL CNTR

STEP26 = IN II01 ;CURR SRG VIOL CNTR

STEP27 = SUB

STEP28 = NOP

STEP29 = NOP

STEP30 = NOP

STEP31 = NOP

STEP32 = NOP

STEP33 = NOP

STEP34 = BIP 38

STEP35 = INC IO01 ;MARG INCR CNTR

STEP36 = CLR RO03 ;TIMER

STEP37 = SET BO02 ;MARG INCR FLAG

STEP38 = IN IO01 ;MARG INCR CNTR

STEP39 = BIZ 43

STEP40 = IN M02 ;EXEC FREQ

STEP41 = DIV M01 ;3600

STEP42 = ADD RO03 ;TIMER HOURS

STEP43 = OUT RO03

STEP44 = IN II01 ;CURR SURGE EVENT CNTR

STEP45 = OUT IO02 ;PREV SURGE EVENT CNTR

STEP46 = NOP

STEP47 = NOP

STEP48 = IN BO02 ;MARG INCR FLAG

STEP49 = OSP M03

STEP50 = OUT BO01 ;MARG INCR ALARM

Control Margin Block Logic Details

Steps 1-9: Calculate the margin increase due to surge point violations and add to the minimum margin RI01. Limit the margin to the maximum in RI02 and store the result to RO02.

Steps 10-14: Subtract the current margin in RO01 and branch to step 15 if the difference is zero or positive. Otherwise, ramp the margin down to the target margin using the ramp rate in RI05.

Steps 15-17: Store the margin change into RO04 and add it to the current margin RO01. Store the new margin to RO01.

Steps 19-23: Clear the margin increase flag BO02. If the manual reset has been triggered (BI02 = 1) then clear the margin increase counter IO01 and the timer RO03.

Step 24: If this is the block initialization pass (BII), go to step 44.

Steps 25-37: If the surge event counter II01 has increased since the previous execution (IO02), then increment the margin increase counter IO01, clear the margin increase timer RO03, and set the margin increase flag BO02.

Steps 38-43: If the margin increase counter IO01 is zero, then zero the margin increase timer RO03 by going to step 43. Otherwise, increase the timer RO03 by the execution frequency converted to hours.

Steps 44-45: Store the surge event counter II01 to the previous surge event counter IO02.

Steps 48-50: Perform a one-shot pulse for M03 seconds based on the margin increase flag BO02 and store the result to the margin increase alarm BO01.

Control Point Block CTL_POINT

CTL_POINT is a CALCA block that determines the control point for anti-surge control. This block also performs the variable margin logic described previously in this document. The following connections are required:

RI01 = Anti-surge flow measurement

RI02 = Anti-surge flow controller setpoint

RI03 = :FLOW_SP.RO01 (surge point in flow units)

RI04 = Anti-surge flow controller output

RI05 = :CTL_MARG.RO01 (control margin)

MA = :SURGE_VIOL.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

RI06 = Variable margin filter factor (must be between 0 and 1)

RI07 = Variable margin control band (flow units)

RI08 = Variable margin ramp rate (flow units per execution)

TIMINI = 3

M01 = Constant 1.0

M02 = Constant 100.0

M03 = Minimum allowed control point (flow units)

M04 = Maximum allowed control point (flow units)

M05 = Anti-surge flow controller output trigger for variable margin ramp (%)

M06 = Tolerance for setting variable margin flag (flow units)

The block generates the following outputs:

RO01 = Anti-surge controller RSP

RO02 = Filtered anti-surge controller measurement

RO03 = Control point

RO04 = Margin for X-Y plot

BO01 = Variable margin flag

M20 = Calculated control margin (1+Margin/100)

Control Point Block Steps

STEP01 = ADD RI05 M02 ;CTL MARG + 100

STEP02 = DIV M02 ;100.0

STEP03 = OUT M20 ;CALC MARG

STEP04 = MUL RI03 ;ASC H TARG

STEP05 = IN M03 ;MIN CTL PT

STEP06 = MAX 2

STEP07 = IN M04 ;MAX CTL PT

STEP08 = MIN 2

STEP09 = OUT RO03 ;CONTROL PT

STEP10 = BII 16

STEP11 = SUB M01 RI06 ;1 – FILT FACT

STEP12 = MUL RI01 ;ASC MEAS

STEP13 = MUL RI06 RO02 ;FILTERED ASC MEAS

STEP14 = ADD 2

STEP15 = GTO 17

STEP16 = IN RI01 ;ASC MEAS

STEP17 = OUT RO02 ;FILTERED ASC MEAS

STEP18 = SUB RI04 M05 ;ASC VALVE – TRIGGER

STEP19 = BIN 22

STEP20 = SUB RI02 RI08 ;ASC SP – RAMP

STEP21 = GTO 25

STEP22 = SUB RO02 RI07 ;FILTERED ASC MEAS – BAND

STEP23 = ADD RI02 RI08 ;ASC SP + RAMP

STEP24 = MIN 2

STEP25 = IN RO03 ;CTL PT

STEP26 = MAX 2

STEP27 = IN M04 ;MAX CTL PT

STEP28 = MIN 2

STEP29 = OUT RO01 ;ASC RSP

STEP30 = CST

STEP31 = MUL M20 M20 ;MARG SQUARED

STEP32 = OUT RO04 ;MARG FOR XY PLOT

STEP33 = CST

STEP34 = SUB RO01 RO03 ;ASC RSP – CTL PT

STEP35 = SUB M06 ;TOLERANCE

STEP36 = SSP BO01 ;VAR MARG FLAG

STEP37 = CLR BO01

STEP38 = END

Control Point Block Logic Details

Steps 1-9: Calculate the control point using equation 8. Store the calculated margin into M20. Limit the control point to the minimum in M02 and the maximum in M03. Store the result to RO03.

Step 10: If this is the block initialization pass (BII), go to step 16 to bypass the filtering operation and store the anti-surge flow measurement RI01 into RO02.

Steps 11-17: Filter the anti-surge flow measurement in RI01 using equation 10 and store the filtered value into RO02.

Steps 18-29: If the anti-surge valve position (RI04) is below the trigger (M05), then ramp the anti-surge controller RSP to the variable margin. The variable margin is the filtered measurement (RO02) minus the variable margin band (RI07). If the anti-surge valve position is at or above the trigger, then ramp the anti-surge controller RSP down to the control point. Limit the RSP to the maximum control point in M03. Store the final RSP to RO01.

Steps 31-32: Square the margin (M20) and store the result to RO04 for use in the X-Y plot.

Steps 34-37: If the difference between the anti-surge controller RSP (RO01) and the control point (RO03) is greater than or equal to the tolerance (M06) then set the variable margin alarm in BO01. Otherwise, clear the alarm.

DCS IMPLEMENTATION – ANTI-SURGE CONTROLLER BLOCKS

Anti-Surge Controller Blocks

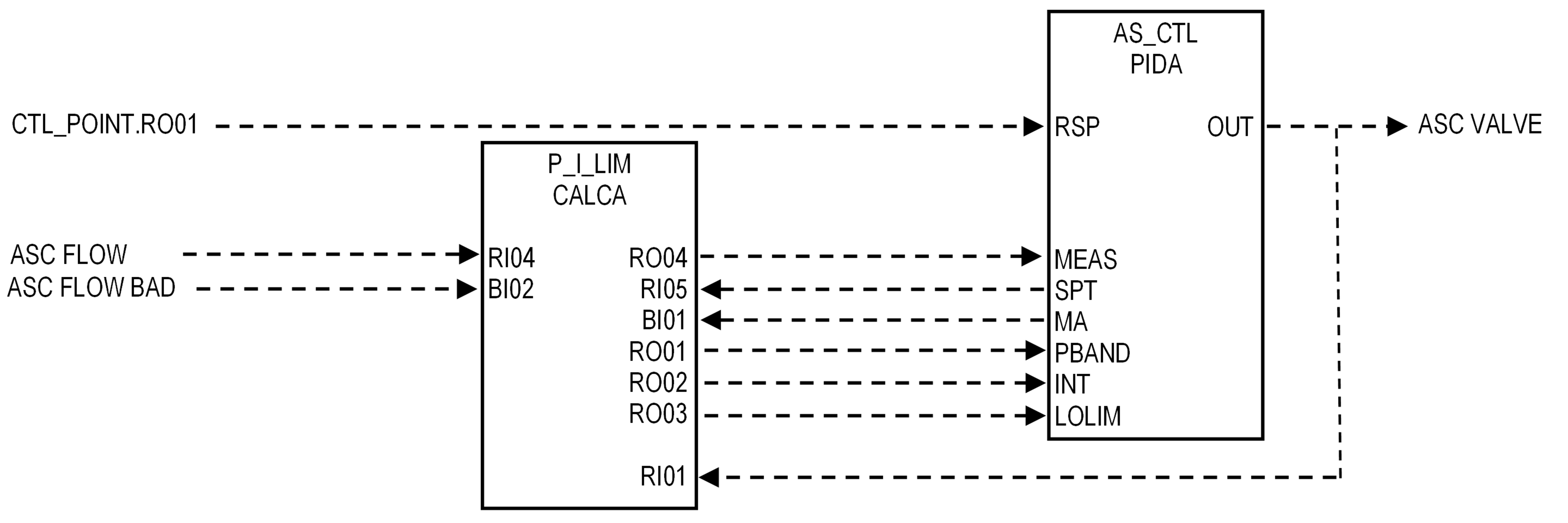

Figure 10 shows the block schematic for the anti-surge controller blocks (should be executed in this order):

- CALCA block that applies adaptive and asymmetric control (P_I_LIM).

PIDA block for anti-surge PID control (AS_CTL).

Asymmetric Control Block P_I_LIM

P_I_LIM is a CALCA block that performs adaptive tuning and asymmetric control logic for the anti-surge controller. The following connections are required:

RI01 = Anti-surge flow controller output

RI04 = Anti-surge flow measurement

RI05 = Anti-surge flow controller setpoint

BI01 = :AS_CTL.MA

BI02 = Anti-surge flow measurement bad status

MA = :P_I_LIM.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

RI02 = Maximum anti-surge valve closing rate (% per execution)

RI06 = Normal PBAND

RI07 = Normal INT

RI08 = anti-surge controller negative deviation at which tuning constants are halved (% of SPT)

TIMINI = 3

M01 = Constant 1.0

M02 = Constant 2.0

M03 = Constant 100.0

M04 = Default anti-surge controller measurement when flow is bad (flow units – must be > zero)

M05 = Bad flow delay on time (sec) before bad input action is taken

M06 = Minimum PBAND

M07 = Minimum INT

The block generates the following outputs:

RO01 = Anti-surge controller PBAND

RO02 = Anti-surge controller INT

RO03 = Anti-surge controller LOLIM

RO04 = Anti-surge controller MEAS

BO01 = Bad input flag

BO01 = Bad input flag (delayed by M05 sec)

M18 = Anti-surge flow % below setpoint

M20 = Calculated adaptive tuning factor

Asymmetric Control Block Steps

STEP01 = RBD RI04 ;ASC MEAS BAD?

STEP02 = OR BI02 ;ASC MEAS BAD?

STEP03 = OUT BO01 ;BAD INPUT FLAG

STEP04 = DON M05 ;DELAY

STEP05 = OUT BO02 ;BAD FLAG DELAYED

STEP06 = IN BO01

STEP07 = BIF 12

STEP08 = IN BO02

STEP09 = BIF 40

STEP10 = IN M04 ;SUBSTITUTE MEAS

STEP11 = GTO 13

STEP12 = IN RI04 ;ASC MEAS

STEP13 = OUT RO04 ;ASC MEAS

STEP14 = CST

STEP15 = IN M02 ;CONSTANT 2.0

STEP16 = IN M01 ;CONSTANT 1.0

STEP17 = IN RI04 ;ASC MEAS

STEP18 = IN RI05 ;ASC SPT

STEP19 = IN M04 ;MIN SPT

STEP20 = MAX 2

STEP21 = DIV

STEP22 = SUB

STEP23 = MUL M03 ;CONSTANT 100.0

STEP24 = OUT M18 ;% BELOW SPT

STEP25 = DIV RI08 ;TUNING HALVED

STEP26 = EXP

STEP27 = IN M01 ;CONSTANT 1.0

STEP28 = MAX 2 ;LIMIT TO MIN 1.0

STEP29 = OUT M20 ;ADAPT TUNE FACT

STEP30 = CST

STEP31 = DIV RI06 M20 ;APPLY TO PBAND

STEP32 = IN M06 ;MIN PBAND

STEP33 = MAX 2

STEP34 = OUT RO01 ;ASC.PBAND

STEP35 = CST

STEP36 = DIV RI07 M20 ;APPLY TO INT

STEP37 = IN M07 ;MIN INT

STEP38 = MAX 2

STEP39 = OUT RO02 ;ASC.INT

STEP40 = CST

STEP41 = RBD RI01 ;BAD ASC.OUT?

STEP42 = BIF 45

STEP43 = CLR

STEP44 = GTO 50

STEP45 = SUB RI01 RI02 ;OUT – RAMP

STEP46 = IN BI01 ;ASC AUTO

STEP47 = MUL 2

STEP48 = IN 0

STEP49 = MAX 2

STEP50 = OUT RO03 ;ASC LOLIM

Asymmetric Control Block Logic Details

Steps 1-5: Check the flow input for bad status and store to BO01. Perform a delay-on operation and store the result to BO02.

Steps 6-7: If the bad flag BO01 is false, then branch to step 12 to store the flow measurement in RI04 to RO04.

Steps 8-9: If the delayed bad flag BO02 is false, then filter out a potential blip in the bad input indication by going to step 40.

Steps 10-13: If the delayed bad flag BO02 is true, then substitute the default value M04 for the measurement by storing it to RO04.

Steps 15-29: Calculate the adaptive tuning factor via equation 13 and store to M20. Protect against dividing by zero by limiting the setpoint to M04. Limit the factor to a minimum of 1.0.

Steps 31-34: Calculate the adaptive PBAND via equation 11, limit the PBAND to a minimum of M06, and store the result to RO01.

Steps 36-39: Calculate the adaptive INT via equation 12, limit the INT to a minimum of M07, and store the result to RO02.

Steps 41-50: If the anti-surge controller output (RI01) is bad or if the anti-surge controller is in manual (BI02), then set the controller low output limit (RO03) to zero. Otherwise, subtract the maximum valve closing rate (RI02) from the current output (RI01) and store the result to the controller low output limit (RO03). Prevent RO03 from going below zero.

Anti-Surge PID Controller AS_CTL

AS_CTL performs the PID algorithm based on the anti-surge flow measurement and the remote setpoint from block CTL_POINT. It then sends its output to the anti-surge control valve. AS_CTL should have the following connections:

MEAS = :P_I_LIM.RO04

RSP = :CTL_POINT.RO01 (control point)

REMSW = :AS_CTL.REMSW.1 (lock in remote)

PBAND = :P_I_LIM.RO01

INT = :P_I_LIM.RO02

LOLIM = :P_I_LIM.RO03

HOLD = :TD_CHECK.BO01 (if block exists)

HOLD = :TS_CHECK.BO01 (if TD_CHECK does not exist)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

HSCI1 = Range of anti-surge flow transmitter

LSCI1 = 0.0

STRKOP = 0 (do not initialize setpoint)

MODOPT = 4 (PI only)

INCOPT = 0

SPLLAG = 1

LIMOPT = 2

MCLOPT = 1

PRIBLK = 0

Note: If the application includes controller decoupling (as described in the SAS functional specification entitled Multi-Section Compressor Controls with Controller Decoupling), then the following parameters must be set accordingly:

BIAS = :DECOUP_AS1.RO01

HOLD = :DECOUP_AS1.BO01

HSCI2 = 999999

LSCI2 = -999999

The BI05 input to the decoupling block DECOUP_AS1 must receive the hold request from either TD_CHECK.BO01 (if it exists) or TS_CHECK.BO01. DECOUP_AS1 then passes it along to AS_CTL.HOLD via its BO01 output.