For Testing Complex Controls

Introduction

In previously released functional specifications, Strategic Automation Services (SAS) described several complex controls, such as centrifugal compressor controls, heater pass outlet temperature balance, advanced distillation overhead controls, and many more. These functional specifications are all on the SAS website.

The complex controls were tested using DCS-based simulation to provide realistic feedback. The purpose of this document is to describe how to build simulation software in standard Foxboro DCS blocks.

Instrument Types

The simulation software must provide inputs for the following instrument types:

- Flows

- Pressures

- Levels

- Temperatures

- Analyzers

Each is discussed separately below.

Flow Simulation – Simple Approach

Flows can be simulated simply or rigorously, depending upon the situation. The simplest approach is usually called loopback. The flow is assumed to be directly proportional to the flow controller output.

F = K * (FCout / 100) (1)

where:

F = simulated flow

K = flow at 100% output

FCout = flow controller output

Control valves exhibiting non-linearity, such as equal percentage, can be simulated using characterizer blocks. However, this complication is seldom warranted.

Before the calculated flow is sent to the controller’s analog input, it should be slightly filtered to simulate a lag. A filter time of 0.03 to 0.10 minutes is usually sufficient.

Flow Simulation – Rigorous Approach

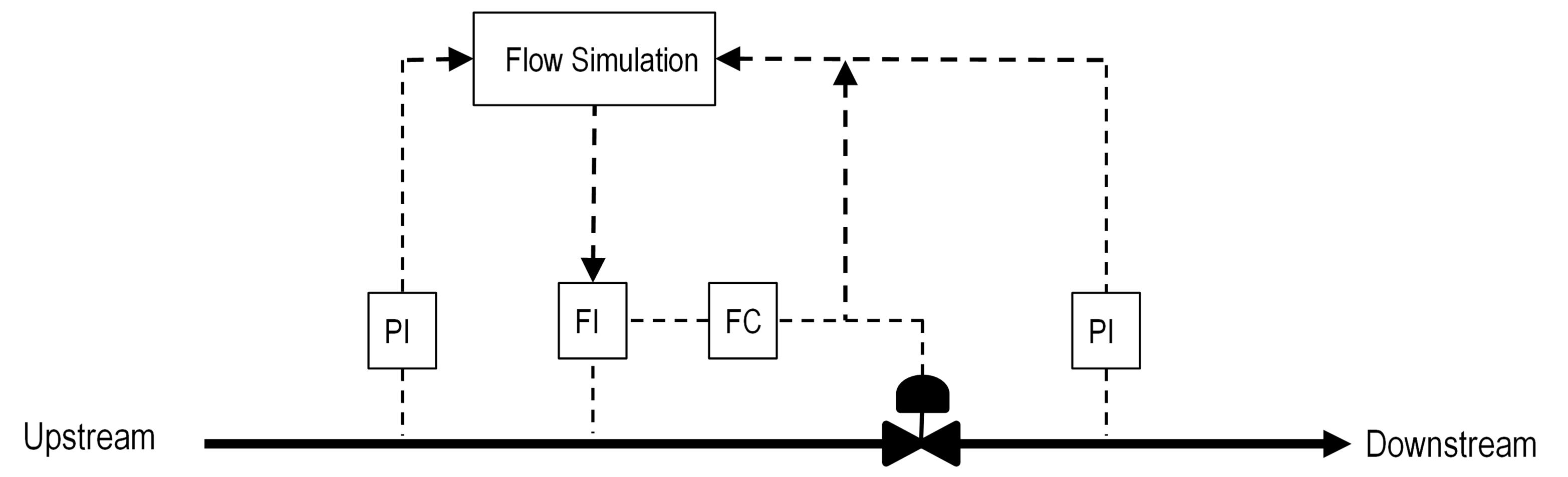

Flow is dependent on the upstream and downstream pressures as well as the control valve position (see Figure 1).

F = K * (FCout / 100) * SQRT [(Pup – Pdn) / Pdref] (2)

where:

F = simulated flow

K = flow at 100% output and pressure differential at Pdref

FCout = flow controller output

SQRT = square root function

Pup = upstream pressure

Pdn = downstream pressure

Pdref = reference differential pressure

Note that equation 2 is the same as equation 1 when the term (Pup – Pdn) is equal to Pdref. Therefore, the same calculation can be used for either approach.

As stated previously, the calculated flow should be slightly filtered to simulate a lag. Noise can be applied for more realism, and a bias can be added to simulate transmitter bias. This approach must be used in pressure-flow networks in which flow and pressure interact (to be discussed later).

Flow Simulation – Centrifugal Compressor Anti-Surge Control

In a previously released SAS functional specification, compressor anti-surge controls are described in some detail. The surge line is defined in terms of pressure ratio (Rc) and suction flow orifice dP:

Rc = Pd / Ps (3a)

hc = hs * Ps / Psr (3b)

where:

Pd = discharge pressure (absolute)

Ps = suction pressure (absolute)

Psr = suction reference pressure at which performance curve data were obtained

hc = suction orifice differential pressure corrected for suction pressure deviation from design (percent of

ange)

hs = suction orifice differential pressure (percent of range)

The value of hc is obtained from the surge line using the current Rc, and then hs is calculated by rearranging equation 3b:

hs = hc * Psr / Ps (3c)

Note that the term hs is at suction conditions. If the flow meter is in the discharge line, then hs must be adjusted to discharge conditions and the anti-surge flow controller setpoint Fo calculated as follows:

ho = hs * (ρor / ρo) * (ρs / ρsr) (4)

Fo = Fmax * SQRT (ho / 100) (5)

where:

ho = orifice differential pressure at discharge conditions

ρo = flowing density at actual orifice conditions

ρor = flowing density at reference orifice conditions

ρs = flowing density at actual suction conditions

ρsr = flowing density at reference suction conditions

Fmax = orifice flow range

For ideal gases, flowing density can be calculated as follows:

ρ = P * M / (R * T * Z) (6)

where:

P = absolute pressure

M = molecular weight

R = ideal gas constant

T = absolute temperature

Z = compressibility

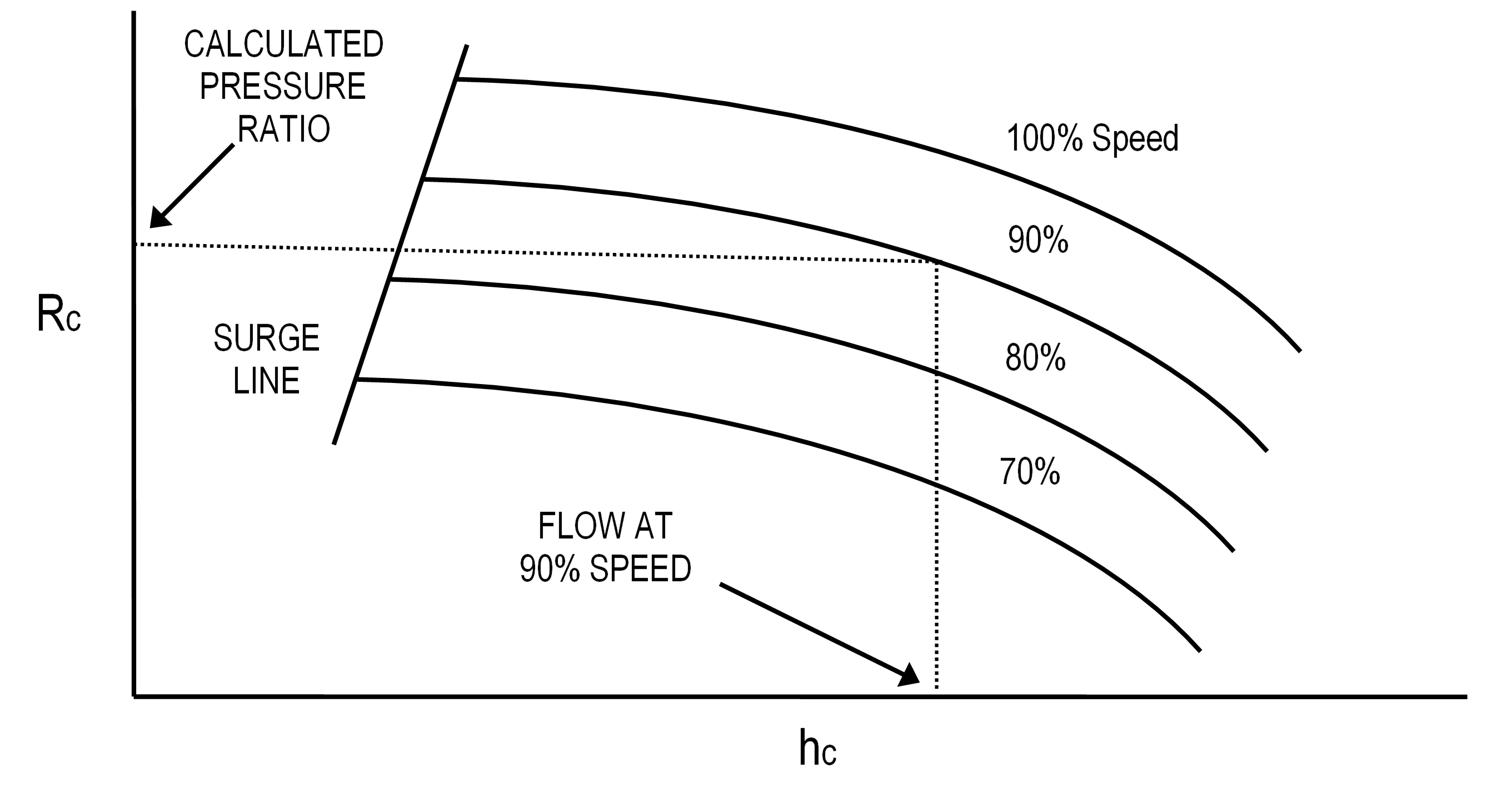

Flow Simulation – Centrifugal Compressor

Like flow through a control valve, flow through a centrifugal compressor is also dependent on the upstream and downstream pressures. However, the flow depends on other factors, such as compressor speed (see Figure 2). The anti-surge control calculations previously discussed can be used to simulate flow through a compressor.

First, the pressure ratio (Rc) must be calculated via equation 3a. Then, the compressor performance curves can be used to lookup the flow hc (as shown by the dashed lines in Figure 2). Finally, equations 3c through 6 can be used to calculate the flow through the compressor.

Note: The flow for speeds between the performance curves must be interpolated.

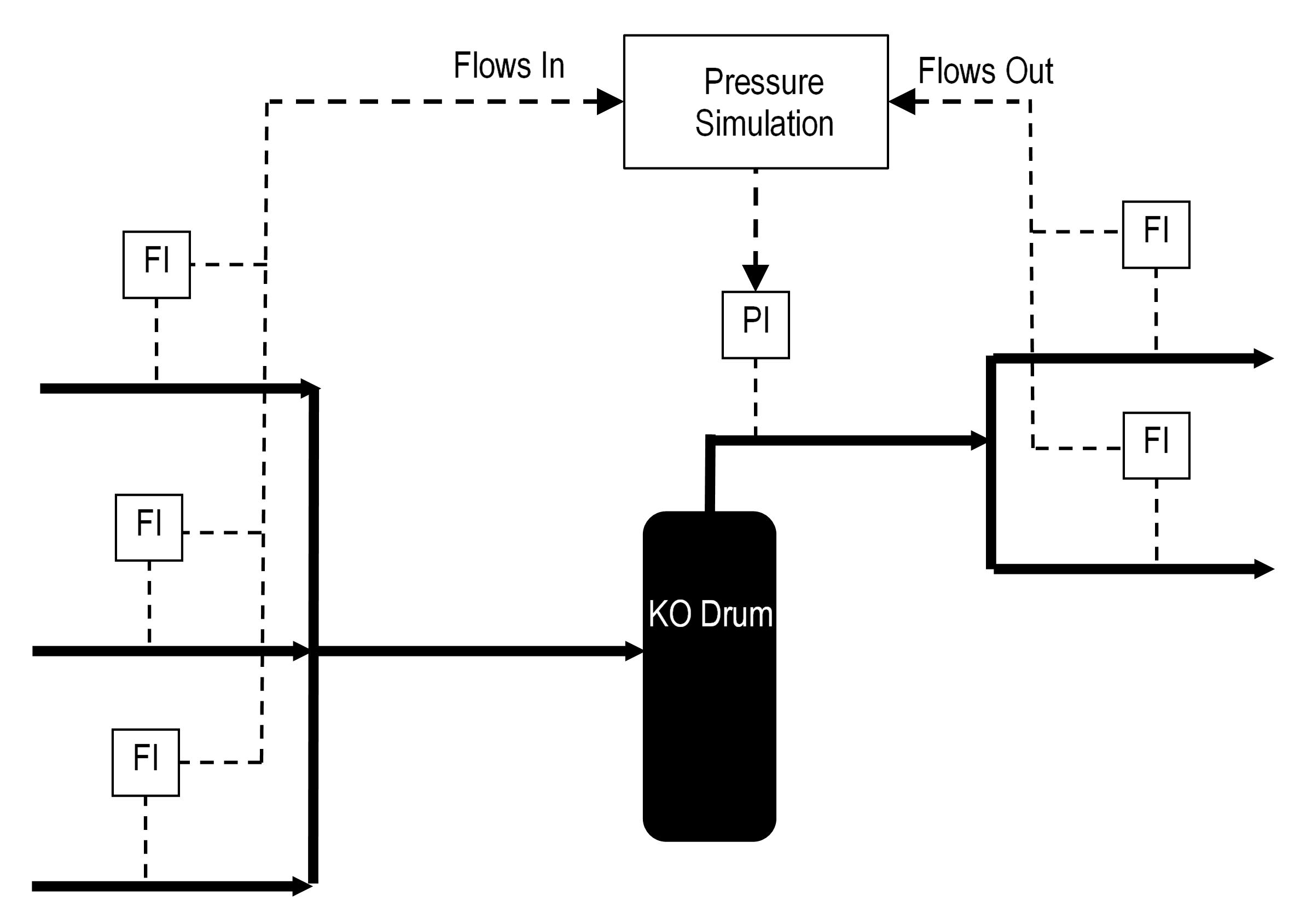

Pressure Simulation

Pressure is dependent on the balance between flows into the node (i.e., sensor location) and flows out (see Figure 3).

P = Pprev + Ka * (ΣFin – ΣFout) (7)

where:

P = simulated pressure

Pprev = previously calculated pressure

Ka = accumulation factor

ΣFin = sum of all flows in

ΣFout = sum of all flows out

Gas flows are used for determining gas pressure and liquid flows are used for determining liquid pressure.

Please note that the current value of the pressure is dependent on the previous value. This feature makes pressure an “integrating” variable. When the flows into the node equal the flows out, then the pressure is unchanged. The pressure changes only when the flows are not balanced.

Before the calculated pressure is sent to the analog input, it should be slightly filtered to simulate a lag. A filter time of 0.03 to 0.10 minutes is usually sufficient.

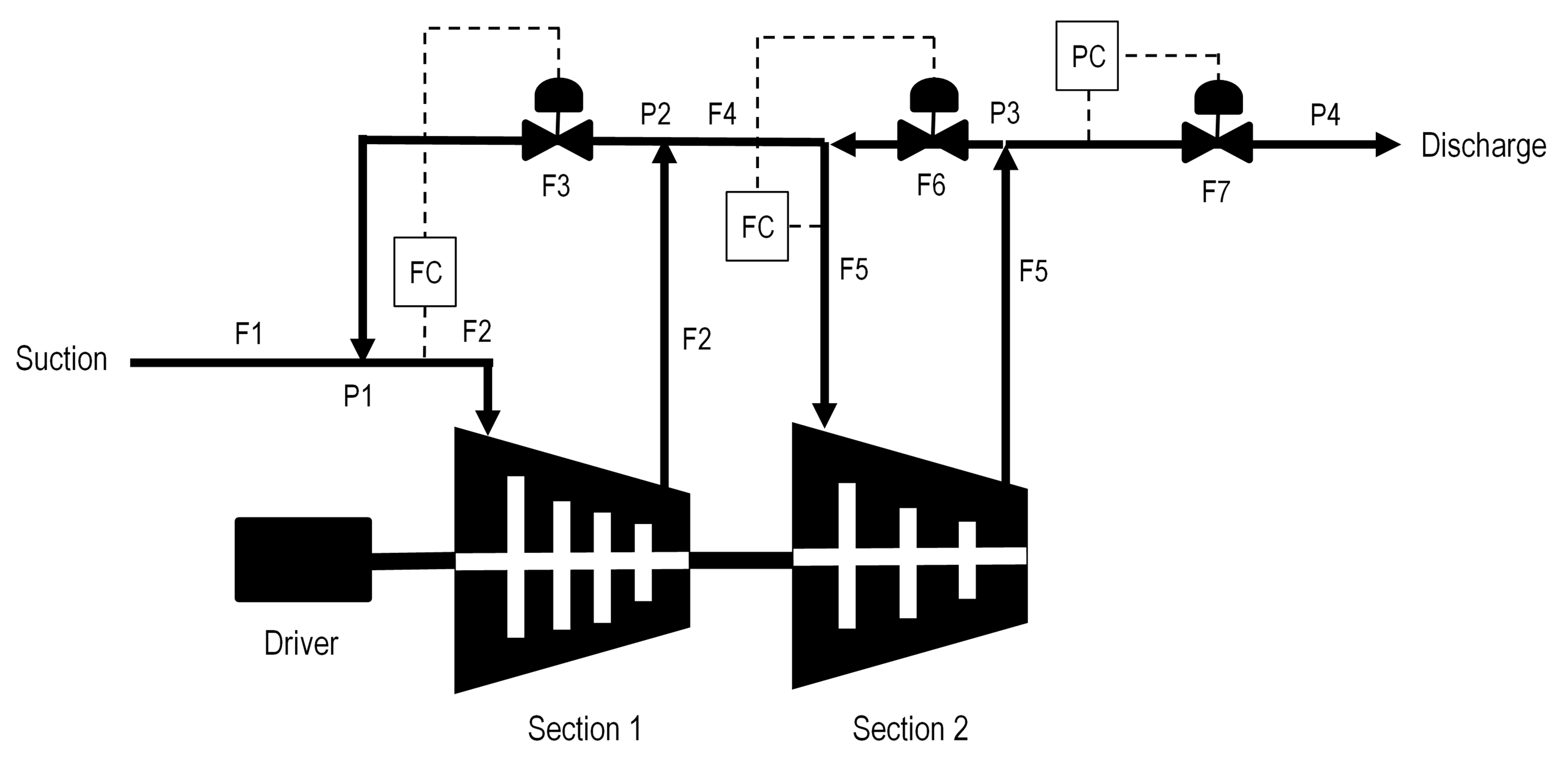

Pressure-Flow Network Simulation

Equations 2 and 3a show that flow is dependent upon pressure and equation 7 shows that pressure is dependent upon flow. In a network such as that in Figure 4, the simulation calculations are highly interactive, requiring an iterative approach. The iterations occur at the block execution frequency, which should be as fast as possible (typically 0.5 seconds). The accumulation factor (Ka) in equation 7 must be tuned to provide rapid convergence without excessive overshoot.

Using the flow and pressure labels in Figure 4, the flows are calculated as follows (F1 and P4 are given):

F2 = f (P1, P2) Note: Eq 3 -6

F3 = K3 * (FCout / 100) * SQRT [(P2 – P1) / Pd3ref]

F4 = F2 – F3

F5 = f (P3, P2) Note: Eq 3 -6

F6 = K6 * (FCout / 100) * SQRT [(P3 – P2) / Pd6ref]

F7 = K7 * (PCout / 100) * SQRT [(P3 – P4) / Pd7ref]

The pressures are calculated as follows:

P1 = P1prev + K1a * (F1 + F3 – F2)

P2 = P2prev + K2a * (F2 + F6 – F3 – F5)

P3 = P3prev + K3a * (F5 – F6 – F7)

The flow simulation block, to be discussed in the DCS Implementation section of this document, includes a feedforward option to speed up convergence. For example, feedforward would be used for flow F7 in Figure 4 so that any change in flow F1 would be immediately passed on to flow F7, rather than waiting for the intermediate flows and pressures to respond.

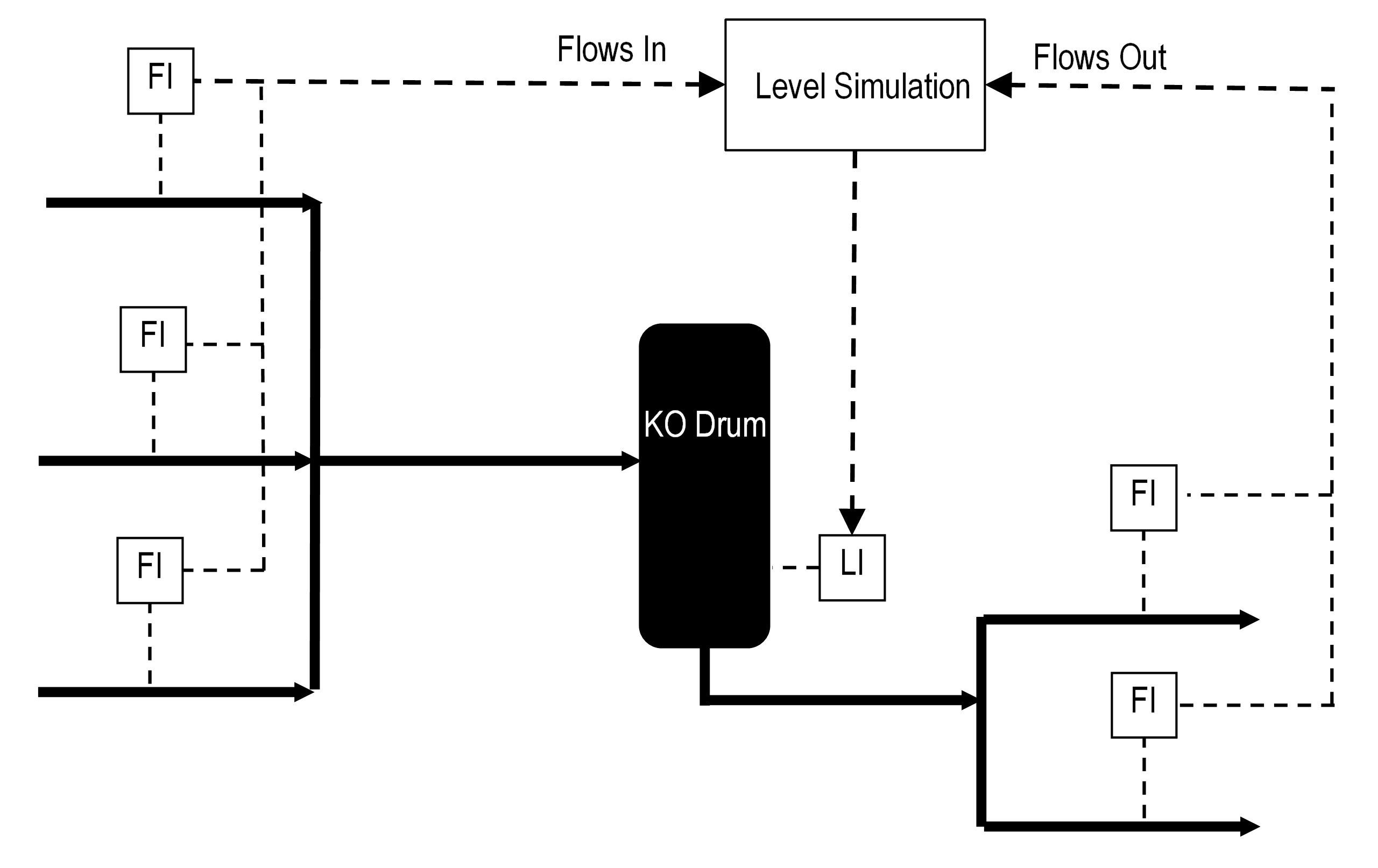

Level Simulation

Level is similar to pressure in that it is dependent on the balance between flows into the vessel and the flows out (see Figure 5). However, the flows are liquid flows in this case.

L = Lprev + Ka * (ΣFin – ΣFout) (8)

where:

L = simulated level

Lprev = previously calculated level

Ka = accumulation factor

ΣFin = sum of all flows in

ΣFout = sum of all flows out

Like pressure, the current value of the level is dependent on the previous value. This feature makes level an “integrating” variable also. When the flows into the vessel equal the flows out, then the level is unchanged. The level changes only when the flows are not balanced.

Before entering the calculation, the individual flows should be filtered to simulate a lag. Flows into the vessel sometimes take more time to affect the level than flows out.

Boiling liquid levels, such as in a boiler steam drum, are more complicated. The level shrinks and swells as the pressure in the drum varies. This discussion does not include boiling levels.

Temperature Simulation

Temperatures have in common the effect of thermal lag. As a result, a considerable lag exists between the manipulated variable and its effect on the temperature. Otherwise, temperatures in general have little in common.

However, the following types of temperatures each have a consistent approach to being simulated:

- Fired heater combined outlet temperature

- Fired heater pass outlet temperatures

- Heat exchanger outlet temperature

- Distillation tray temperature

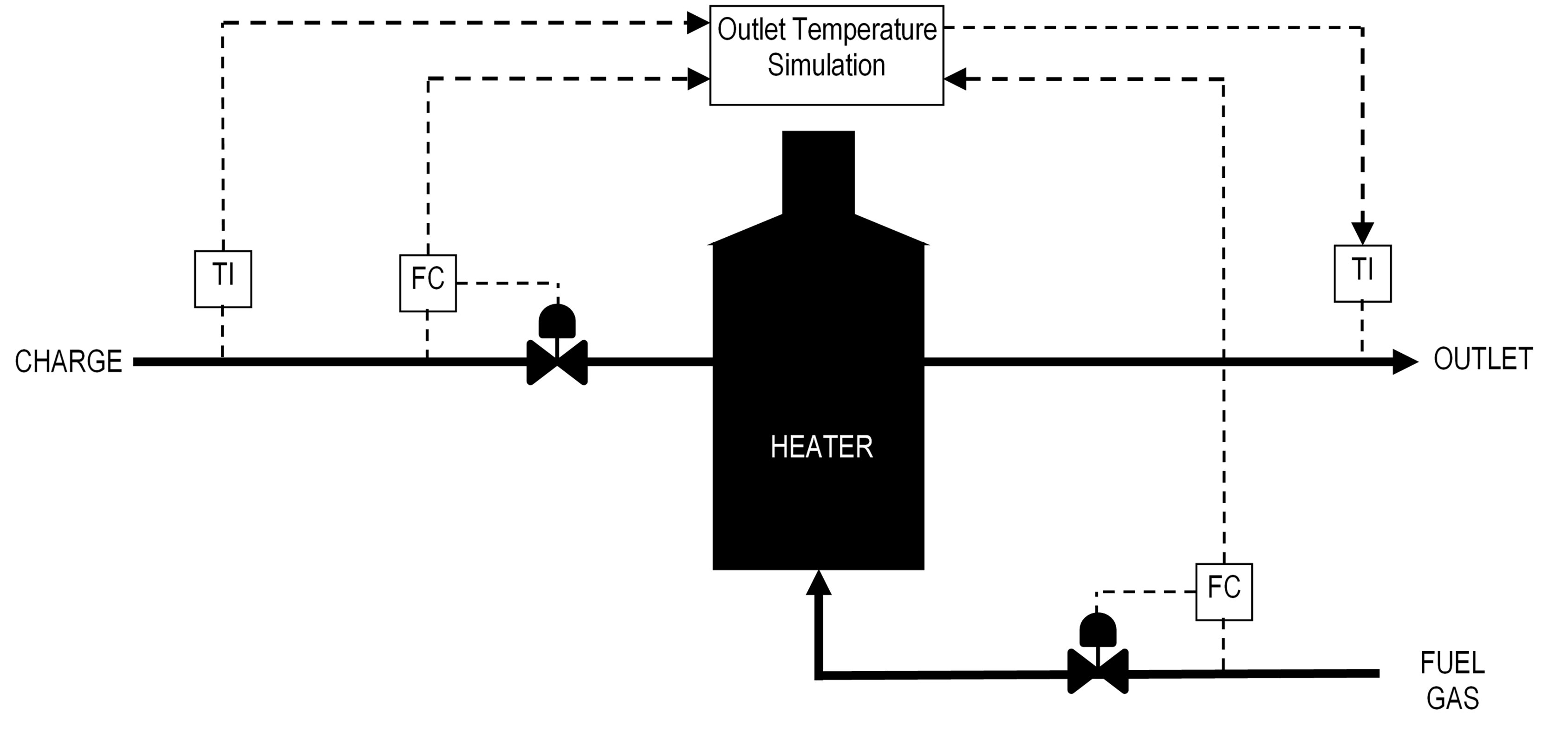

Temperature Simulation – Fired Heater Combined Outlet

The fired heater outlet temperature is dependent on several factors (see Figure 6). First, the heat released by the fuel is calculated in equation 9 (fuel gas is assumed):

Qrel = Htval * Ffuel (9)

Next, the heat absorbed by the feed to the heater is calculated using the heater efficiency:

Qabs = Qrel * Eff / 100 (10)

The heat absorbed can be related to the outlet temperature via the sensible heat equation:

Qabs = Cp * Ffeed * (Tout – Tin) (11)

The left-hand terms of equations 10 and 11 can be set equal and rearranged to obtain equation 12:

Tout = Htval * Eff * Ffuel / (100 * Cp * Ffeed) + Tin (12)

where:

Qrel = heat released from fuel (MMBTU/Hr)

Qabs = heat absorbed by feed (MMBTU/Hr)

Htval = fuel gas heating value (BTU/MSCF)

Ffuel = fuel gas flow (MSCF/Hr)

Eff = heater efficiency (%)Cp = feed heat capacity (MBTU/B-DegF)

Ffeed = feed flow (B/Hr)

Tin = feed inlet temperature (DegF)

Tout = feed outlet temperature (DegF)

Before entering the calculation, the individual variables should be filtered to simulate a lag. The heat curve of vaporizing feeds can be approximated by using average liquid heat capacity.

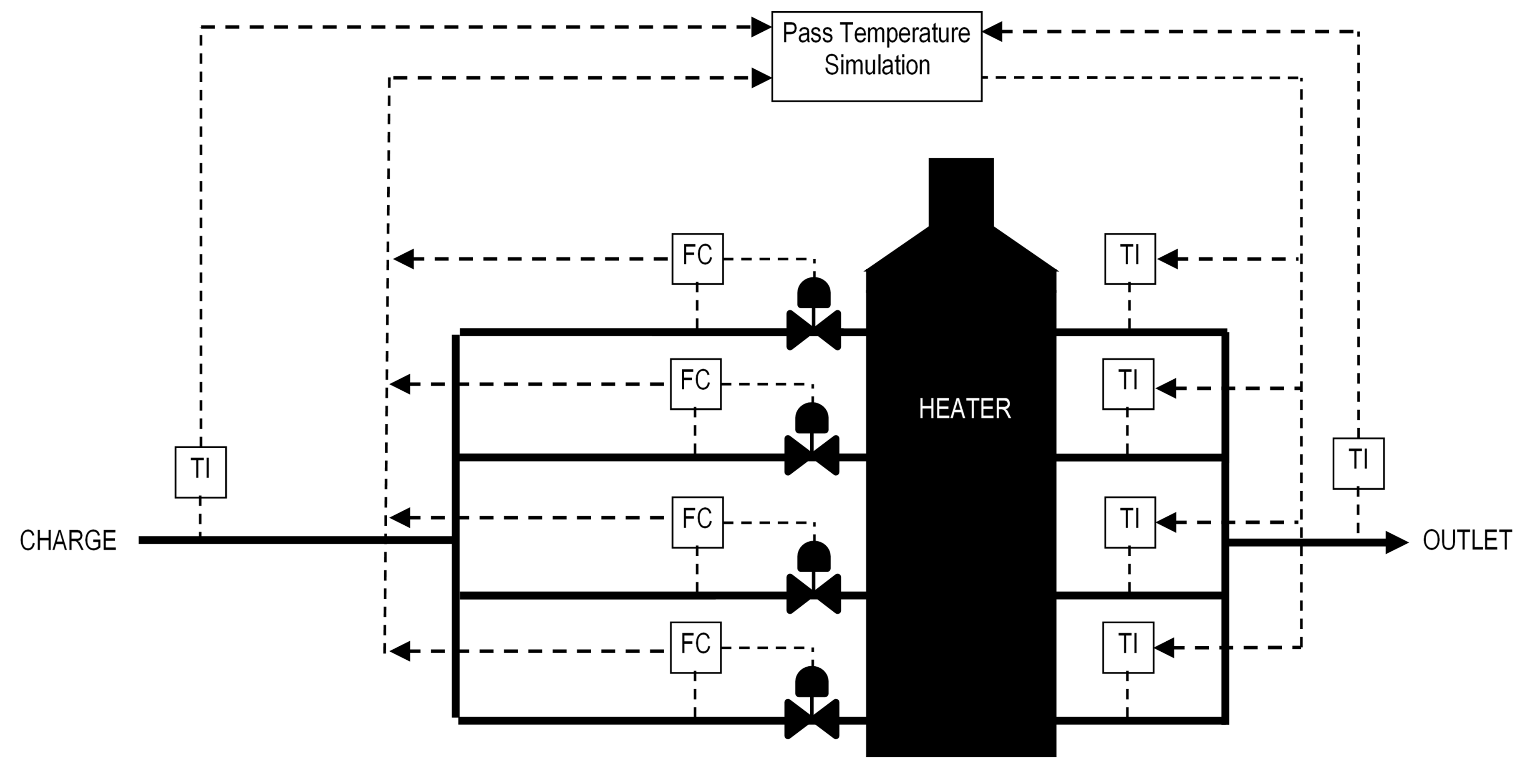

Temperature Simulation – Heater Pass Outlets

The fired heater pass outlet temperatures can be simulated as follows (see Figure 7):

Ftot = ΣFi (13)

dTi = [(Ri * Ftot – Fi) / Fi] * (Tout – Tin) (14)

Ti = Tout + dTi (15)

where:

Ftot = total of all pass flows

Fi = pass i flow

dTi = pass i temperature deviation from combined outlet temperature

Ri = pass i flow ratio target for balanced temperature

Tin = heater inlet temperature

Tout = combined outlet temperature

Ti = pass i outlet temperature

Before entering the calculation, the individual variables should be filtered to simulate a lag.

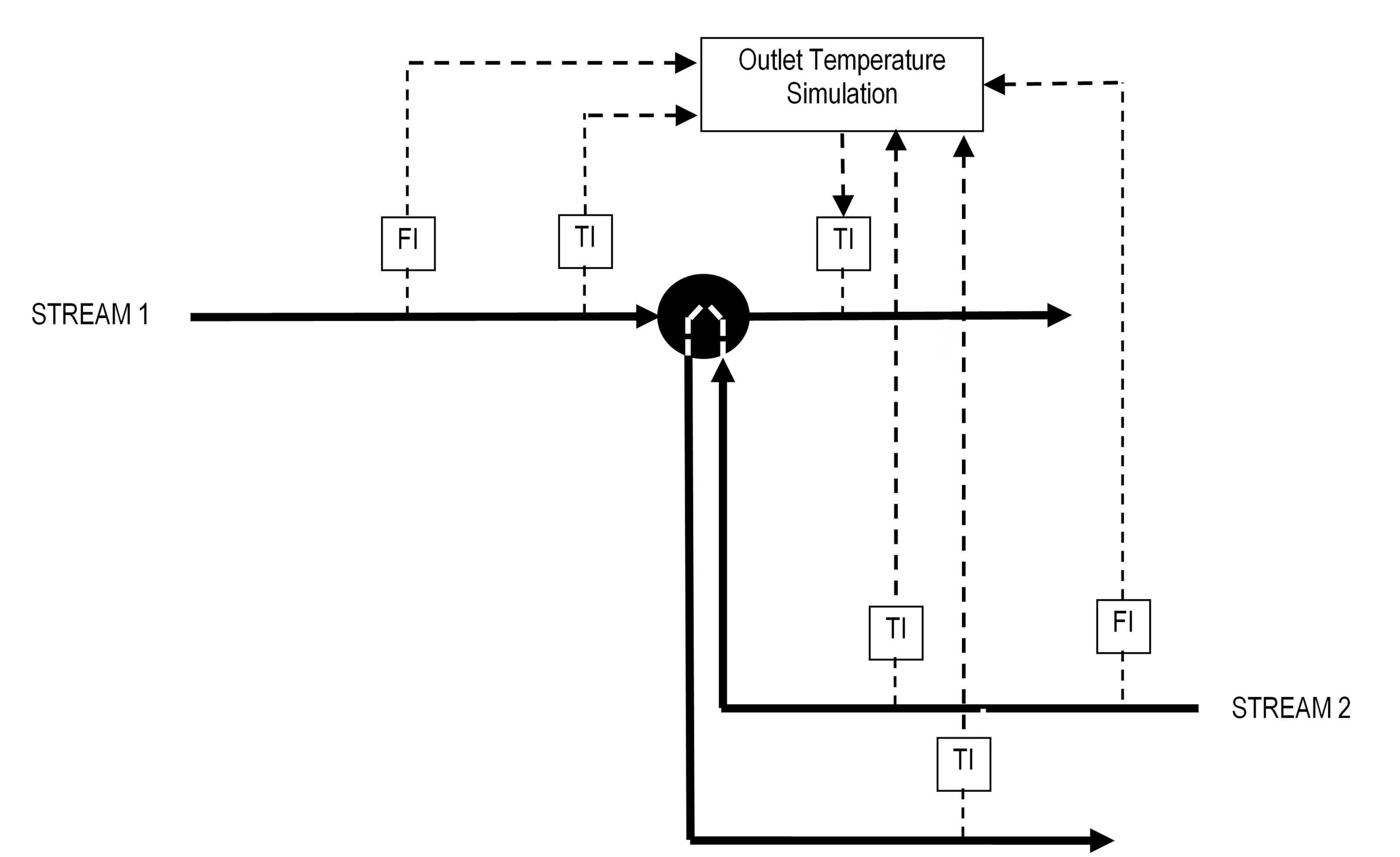

Temperature Simulation – Heat Exchanger Outlet

The outlet temperature of a shell-and-tube heat exchanger can be simulated via the sensible heat equation (see Figure 8):

Q = Cp1 * F1 * (Tin1 – Tout1) (16)

Q = Cp2 * F2 * (Tout2 – Tin2) (17)

Equation 17 can be rearranged to obtain equation 18 with Q being calculated using equation 16:

Tout2 = Q / (Cp2 * F2) + Tin2 (18)

where:

Q = heat transferred (MMBTU/Hr)

Cp1 = stream 1 heat capacity (MBTU/B-DegF)

F1 = steam 1 flow (B/Hr)

Tin1 = stream 1 inlet temperature (DegF)

Tout1 = stream 1 outlet temperature (DegF)

Cp2 = stream 2 heat capacity (MBTU/B-DegF)

F2 = steam 2 flow (B/Hr)

Tin2 = stream 2 inlet temperature (DegF)

Tout2 = stream 2 outlet temperature (DegF)

If stream1 is condensing steam, then Equation 16 can be used by entering the latent heat into Cp1, the constant 1.0 into Tin1, and the constant 0.0 into Tout1.

Before entering the calculation, the individual variables should be filtered to simulate a lag. Note: Stream 2 is being heated by stream 1 in equations 16-18.

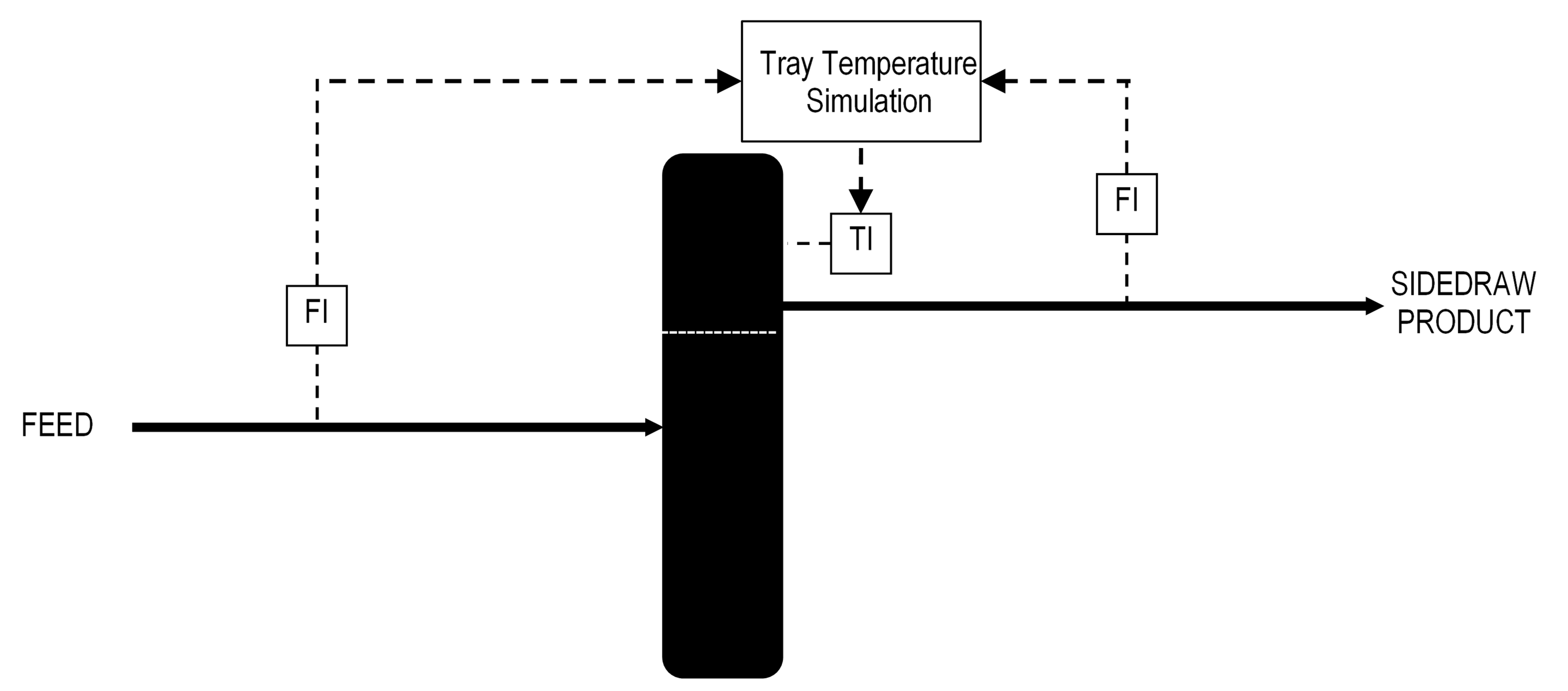

Temperature Simulation – Distillation Tray

The tray temperature in a distillation column can be simulated by characterizing it versus the manipulated variable. For example, the tray temperature in Figure 9 is dependent primarily on the sidedraw product yield (i.e., ratio of product to feed flow). As the yield increases, the temperature will increase due to heavier components being drawn up to the tray. Therefore, the tray temperature should be controlled by manipulating the sidedraw yield.

The yield must first be calculated and then lag and deadtime applied to it before entering the characterization.

Analyzer Simulation

Like temperatures, analyzer inputs in general have very little in common. However, the following types of analyzers each have a consistent approach to being simulated:

- Distillation tray composition

- pH

- Fired heater stack oxygen

Analyzer Simulation – Distillation Tray

The tray composition in a distillation column can be simulated by characterizing it versus the tray temperature. For example, an increasing temperature indicates that heavier components are being drawn up to the tray.

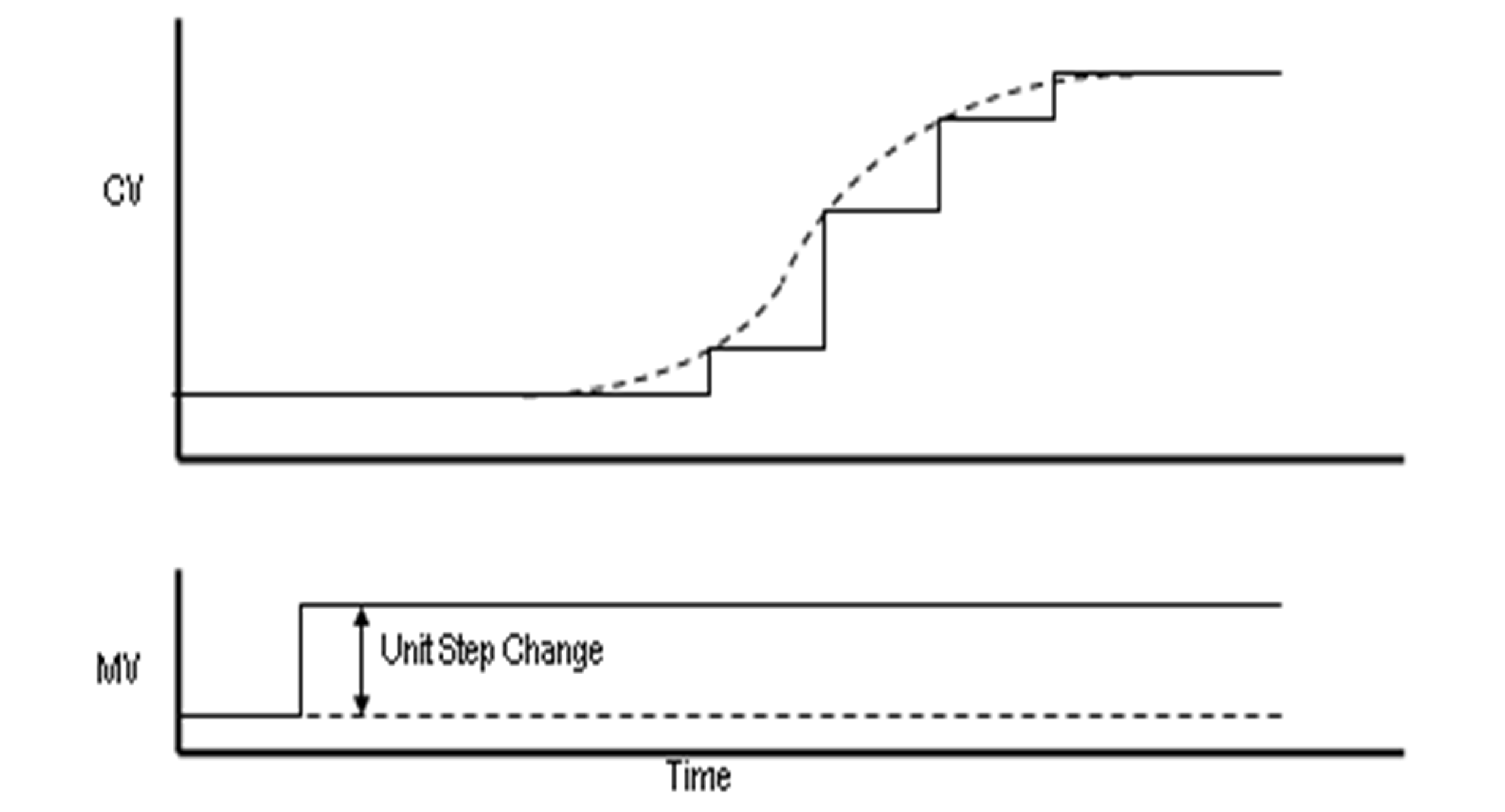

The temperature should have deadtime and lag applied to it before entering the characterization. In addition, the tray analyzer is typically a gas chromatograph that updates the composition at a set cycle. In between updates, the signal is steady. Figure 10 shows the analyzer’s stair-step response to a change in the manipulated variable.

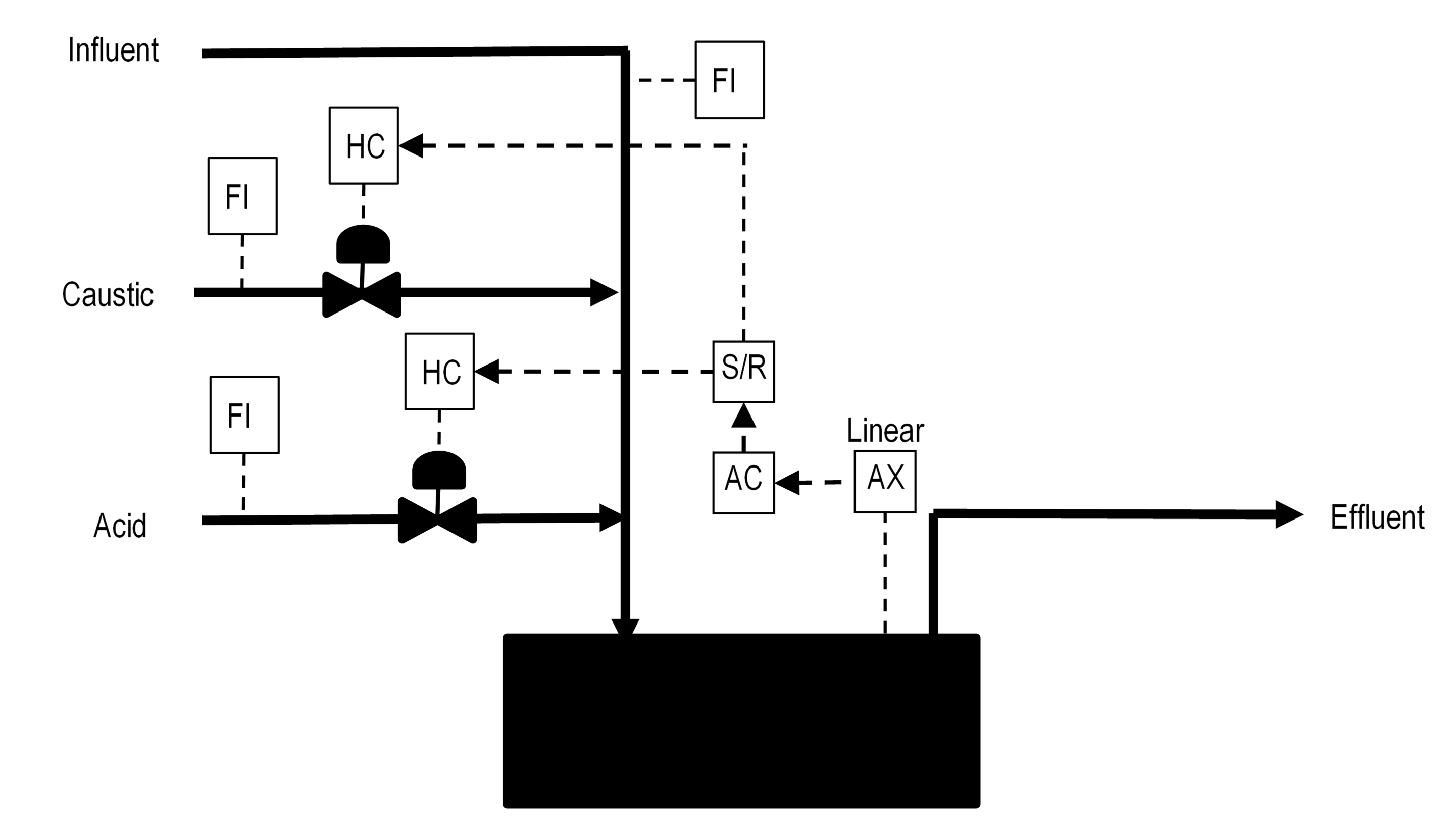

Analyzer Simulation – pH

Figure 11 shows a typical pH control strategy. The influent is treated with either a strong caustic or a strong acid to achieve a setpoint pH for the effluent. The pH can be simulated using the following inputs:

- Influent flow (Fi)

- Caustic flow (Fc) and pH

- Acid flow (Fa) and pH

pH is defined via the following equation:

pH = -log10[H+] (19)

where:

[H+] = concentration of hydrogen ions (kg-ions/m3).

As equation 19 indicates, a linear change in the hydrogen ion concentration results in a logarithmic, or highly nonlinear, change in pH. Therefore, the standard PID algorithm will have great difficulty controlling pH over any sizable range. A previously released SAS functional specification described how to linearize the pH input (MEAS) to a PID controller (AC in Figure 11):

MEAS = SCALE * [10pH-14 – 10-pH] (20)

where:

SCALE = arbitrary scaling factor.

Equation 20 can be used to linearize the pH of each stream. Then, the linearized pH can be blended linearly to obtain the linearized pH of the effluent:

MEASe = (Fi * MEASi + Fc * MEASc + Fa *MEASa) / (Fi + Fc + Fa) (21)

Finally, the effluent linearized pH (MEASe ) can be converted to pH via a characterizer based on equation 20. The calculated pH should have lag and deadtime applied.

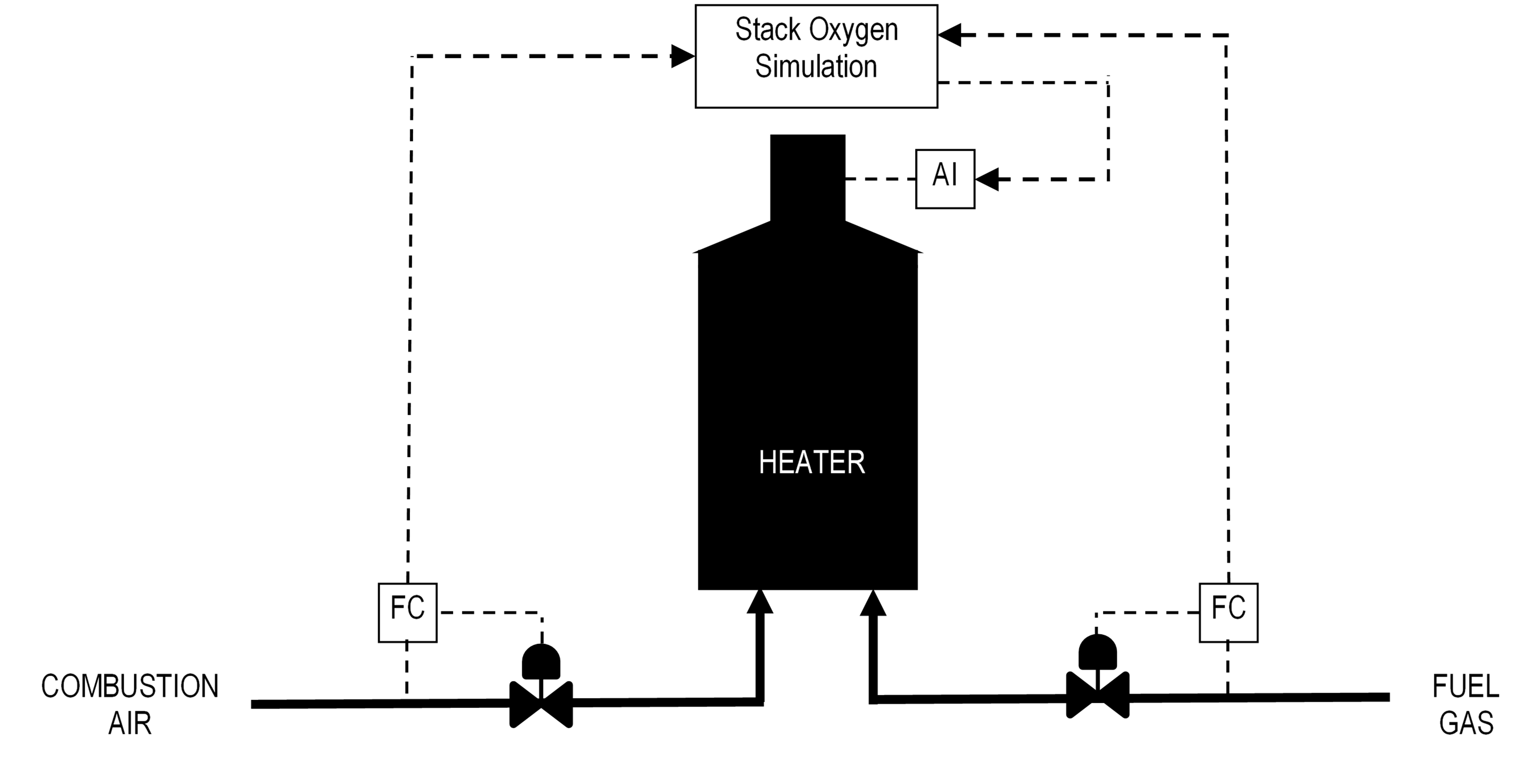

Analyzer Simulation – Fired Heater Stack Oxygen

The fired heater excess oxygen rate is basically the difference between the combustion air flow and the fuel combusted:

FO2 = 0.21 * Fair – O2req * Ffuel (22)

where:

FO2 = excess oxygen rate (MSCF/Hr)

Fair = combustion air rate (MSCF/Hr)

O2req = O2 required for complete combustion of the fuel (SCF/SCF)

Ffuel = fuel gas flow (MSCF/Hr)

The percent oxygen is the excess oxygen rate divided by the flue gas rate:

Fflue = Ffuel + Fair (23)

O2% = 100 * FO2 / Fflue (24)

where:

Fflue = flue gas rate (MSCF/Hr)

O2% = stack oxygen (%)

Before entering the calculation, the individual variables should be filtered to simulate a lag.

DCS IMPLEMENTATION – FLOW SIMULATION

Flow Simulation Block

The flow simulation block is a CALCA block that performs the calculation in equation 2. The following connections are required:

RI01 = Valve position (%)

RI02 = Upstream pressure (PSIG)

RI03 = Downstream pressure (PSIG)

RI06 = Feedforward flow input (lock to zero if not used)

RI07 = Feedforward adaptive gain factor (lock to one if not used)

MA = Lock to auto

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

RI04 = Simulated flow filter factor (set between 0.0 [no filter] and 1.0 [total filter])

RI05 = Flow at 100% output and at pressure differential Pdref (K in equation 2)

RI08 = Feedforward gain factor used to attenuate the feedforward action

TIMINI = 3

M01 = 100

M02 = Reference differential pressure (Pdref in equation 2)

M03 = 0.5

M04 = 1.0

M05 = Minimum flow (usually zero)

M06 = Maximum flow (usually flow transmitter range)

M07 = Simulated transmitter bias (flow units)

M08 = Maximum simulated noise (flow units)

The block generates the following outputs:

RO01 = Simulated flow (filtered and with noise applied)

RO02 = Simulated flow (filtered and without noise applied)

RO03 = Unfiltered flow (without noise applied)

RO04 = Previous value of feedforward input

M11 = Actual differential pressure (Pup – Pdn in equation 2)

M12 = Simulated flow without feedforward action

M13 = Feedforward action

Flow Simulation Block Steps

STEP01 = DIV RI01 M01 ;PCT TO FRACT

STEP02 = SUB RI02 RI03 ;DELTA P

STEP03 = IN 0

STEP04 = MAX 2

STEP05 = OUT M11 ;DELTA P

STEP06 = DIV M02 ;REF DP

STEP07 = SQRT

STEP08 = MUL 2

STEP09 = MUL RI05 ;SCALE FACTOR

STEP10 = ADD M07 ;BIAS

STEP11 = OUT M12 ;FLOW W/O FF

STEP12 = CST

STEP13 = BII 17

STEP14 = SUB RI06 RO04 ;FF CHANGE

STEP15 = MUL RI07 ;ADAPT GAIN

STEP16 = MUL RI08 ;FF GAIN

STEP17 = OUT M13 ;FF ACTION

STEP18 = IN RI06 ;CURR FF INPUT

STEP19 = OUT RO04 ;PREV FF

STEP20 = ADD M12 M13 ;TOT FLOW

STEP21 = IN M05 ;MIN FLOW

STEP22 = MAX 2

STEP23 = IN M06 ;MAX FLOW

STEP24 = MIN 2

STEP25 = OUT RO03 ;UNFILTERED FLOW

STEP26 = BII 32

STEP27 = SUB M04 RI04 ;1 – FILT FACTOR

STEP28 = MUL RO03 ;UNFILT FLOW

STEP29 = MUL RI04 RO02 ;FILT * FILTERED FLOW

STEP30 = ADD 2

STEP31 = GTO 33

STEP32 = IN RO03 ;UNFILT FLOW

STEP33 = OUT RO02 ;FILTERED FLOW

STEP34 = CST

STEP35 = RAND ;RANDOM NO. (0 TO 1)

STEP36 = SUB M03 ;CONSTANT 0.5

STEP37 = MUL M08 ;MAX NOISE

STEP38 = ADD RO02

STEP39 = OUT RO01 ;FLOW W/ NOISE

STEP40 = END

Flow Simulation Block Logic Details

Steps 1-9: Perform calculation shown in equation 2. Limit the pressure drop to a minimum of zero and store to M11.

Steps 10-11: Apply the simulated transmitter bias M07 and store the result to M12.

Steps 13: If this is the block initialization pass (BII), then go to step 17 where the feedforward action M13 is zeroed.

Steps 14-17: Calculate the change in the feedforward input and apply the adaptive gain (RI07) and the feedforward gain (RI08). Store the result to M13.

Steps 18-19: Store the current feedforward input to the previous value (RO04) for the next execution.

Steps 20-25: Add the calculated flow (M12) and the feedforward action (M13), limit the result to the minimum flow (M05) and the maximum flow (M06), and store the result to RO03.

Steps 26: If this is the first time the block is being executed (BII=1), then go to step 32 to bypass the filtering calculation because it uses a value from the previous execution.

Steps 27-33: Perform the filtering calculation. Filtering is done by taking a fraction (RI04) of the previous value (RO02), one minus that fraction times the new value (RO03), and adding the two terms together. The filtered value is stored in RO02.

Steps 35-39: Simulate noise by generating a random number (RAND) between 0 and 1, subtracting 0.5, and multiplying by the maximum noise level (M08). Add the noise to the filtered flow (RO02) and store the result to RO01.

DCS IMPLEMENTATION – COMPRESSOR SIMULATION

Compressor Simulation Blocks

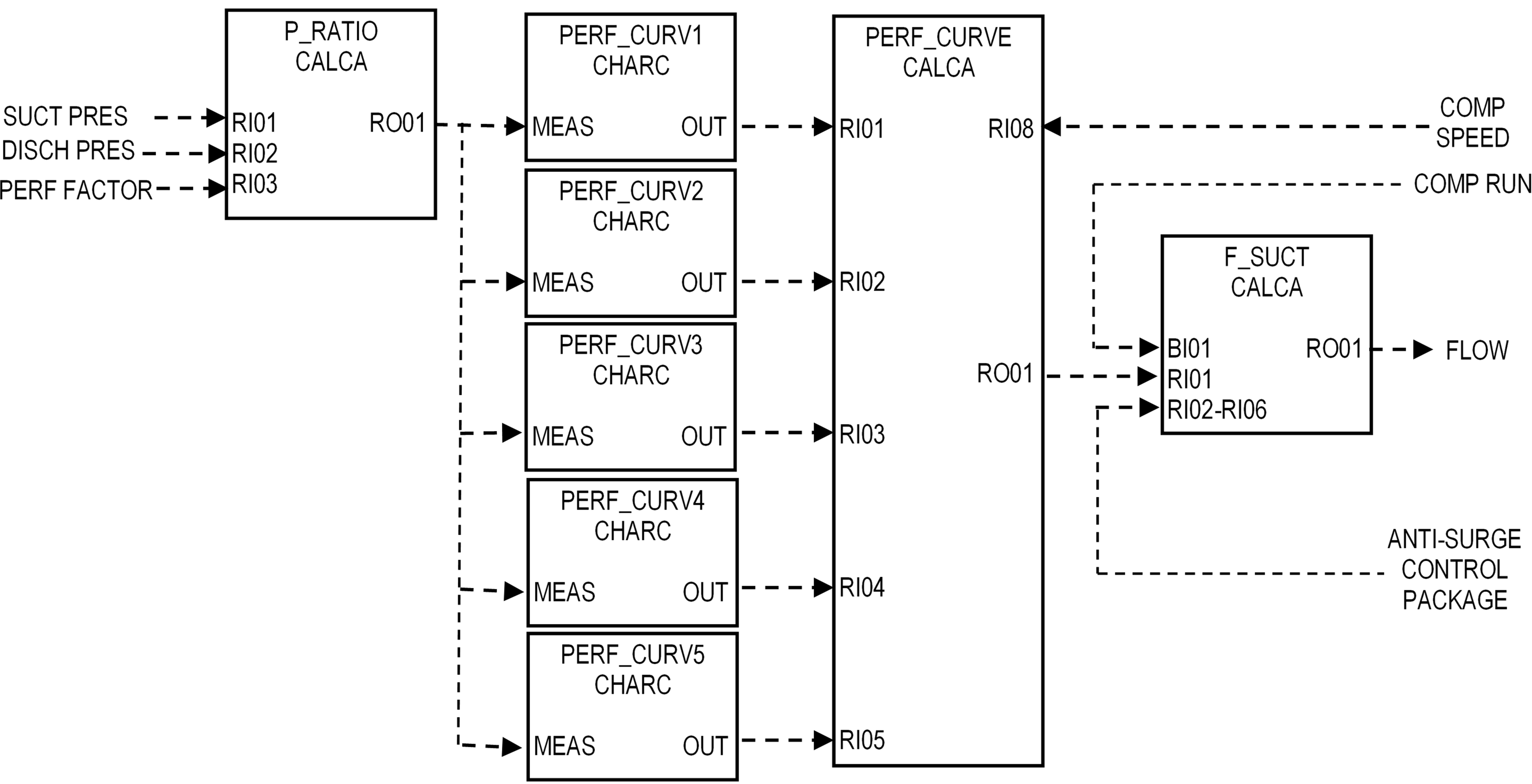

Figure 13 shows the block schematic for a typical compressor simulation. The application contains the following blocks (should be executed in this order):

- CALCA block for calculating pressure ratio (P_RATIO).

- CHARC block for performance curve at lowest speed (PERF_CURV1).

- CHARC block for performance curve at next speed (PERF_CURV2).

- CHARC block for performance curve at next speed (PERF_CURV3).

- CHARC block for performance curve at next speed (PERF_CURV4).

- CHARC block for performance curve at highest speed (PERF_CURV5).

- CALCA block for interpolating the performance curves (PERF_CURVE).

- CALCA block for converting performance curve output to flow (F_SUCT).

Pressure Ratio Block P_RATIO

P_RATIO is a CALCA block that calculates the pressure ratio via equation 3a. The block also applies the performance factor that allows the engineer to vary the compressor performance in the simulation. The following connections are required:

RI01 = Suction pressure

RI02 = Discharge pressure

RI03 = Performance factor (%)

MA = :P_RATIO.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

TIMINI = 3

M01 = 0.0 if suction pressure is PSIA or 14.7 if PSIG

M02 = 0.0 if discharge pressure is PSIA or 14.7 if PSIG

M03 = 100.0

M04 = 1.0

The block generates the following outputs:

RO01 = Pressure ratio modified by performance factor

RO02 = Calculated pressure ratio

Pressure Ratio Block Steps

STEP01 = IN RI02 ;DISCH P

STEP02 = ADD M02 ;CONV DISCH TO ABS P

STEP03 = IN RI01 ;SUCT P

STEP04 = ADD M01 ;CONV SUCT TO ABS P

STEP05 = DIV

STEP06 = OUT RO02 ;PRES RATIO

STEP07 = MUL M03 ;CONSTANT 100.0

STEP08 = DIV RI03 ;PERF FACTOR

STEP09 = MAX M04 ;LIMIT TO 1.0 MIN

STEP10 = OUT RO01 ;MOD PRES RATIO

STEP11 = END

Performance Curve Block PERF_CURV1

PERF_CURV1 is a CHARC block that contains the performance curve for one speed on the performance chart (see Figure 2). The points are entered as x-y pairs, where x is the pressure ratio Rc and y is the orifice differential pressure hc.

The following connections are required:

MEAS = :P_RATIO.RO01

MA = :PERF_CURV1.MA.1 (lock to auto)

The following parameters must be set accordingly:

HSCO1 = Highest value of hc allowed

LSCO1 = Lowest value of hc allowed

ENDP = Number of points entered from performance curve

X_1 = 1.0 (minimum pressure ratio)

Y_1 = hc at X_1 pressure ratio

X_2 = Next higher pressure ratio

Y_2 = hc at X_2 pressure ratio

: :

X_n = Highest pressure ratio (n = value in ENDP)

Y_n = hc at X_n pressure ratio

Each speed on the performance chart must have its own CHARC block named PERF_CURV2, …3, etc. up to five. If the compressor is driven by a fixed speed motor, then only one curve is needed.

Performance Curve Interpolation Block PERF_CURVE

PERF_CURVE is a CALCA block that interpolates the value of hc from the performance curve blocks PERF_CURV1, …2, etc. The following connections are required:

RI01 = :PERF_CURV1.OUT

RI02 = :PERF_CURV2.OUT

RI03 = :PERF_CURV3.OUT

RI04 = :PERF_CURV4.OUT

RI05 = :PERF_CURV5.OUT

RI08 = Compressor speed

MA = :PERF_CURVE.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

TIMINI = 3

M01 = Speed corresponding to performance curve in PERF_CURV1

M02 = Speed corresponding to performance curve in PERF_CURV2

M03 = Speed corresponding to performance curve in PERF_CURV3

M04 = Speed corresponding to performance curve in PERF_CURV4

M05 = Speed corresponding to performance curve in PERF_CURV5

M08 = 1.0

The block generates the following output:

RO01 = Value of hc interpolated from the performance curves

This block is not required for fixed speed motor-driven compressors because only one performance curve exists.

Performance Curve Interpolation Block Steps

STEP01 = SUB RI08 M02 ;PERF CURVE 2

STEP02 = BIP 12

STEP03 = IN RI01 ;PERF CURVE 1

STEP04 = OUT M11

STEP05 = IN RI02 ;PERF CURVE 2

STEP06 = OUT M12

STEP07 = IN M01 ;SPEED 1

STEP08 = OUT M13

STEP09 = IN M02 ;SPEED 2

STEP10 = OUT M14

STEP11 = GTO 42

STEP12 = SUB RI08 M03 ;PERF CURVE 3

STEP13 = BIP 23

STEP14 = IN RI02 ;PERF CURVE 2

STEP15 = OUT M11

STEP16 = IN RI03 ;PERF CURVE 3

STEP17 = OUT M12

STEP18 = IN M02 ;SPEED 2

STEP19 = OUT M13

STEP20 = IN M03 ;SPEED 3

STEP21 = OUT M14

STEP22 = GTO 42

STEP23 = SUB RI08 M04 ;PERF CURVE 4

STEP24 = BIP 34

STEP25 = IN RI03 ;PERF CURVE 3

STEP26 = OUT M11

STEP27 = IN RI04 ;PERF CURVE 4

STEP28 = OUT M12

STEP29 = IN M03 ;SPEED 3

STEP30 = OUT M13

STEP31 = IN M04 ;SPEED 4

STEP32 = OUT M14

STEP33 = GTO 42

STEP34 = IN RI04 ;PERF CURVE 4

STEP35 = OUT M11

STEP36 = IN RI05 ;PERF CURVE 5

STEP37 = OUT M12

STEP38 = IN M04 ;SPEED 4

STEP39 = OUT M13

STEP40 = IN M05 ;SPEED 5

STEP41 = OUT M14

STEP42 = SUB M12 M11

STEP43 = SUB M14 M13

STEP44 = IN M08 ;CONSTANT 1.0

STEP45 = MAX 2

STEP46 = DIV

STEP47 = SUB RI08 M13

STEP48 = MUL 2

STEP49 = ADD M11

STEP50 = OUT RO01 ;%HC

Performance Curve Interpolation Block Logic Details

Steps 1-11: Determine if current speed (RI08) is between curve 1 speed (M01) and curve 2 speed (M02). If not, then go to step 12. Otherwise, store hc values from curves 1 and 2 into M11 and M12, and speeds into M13 and M14. Go to step 42 to perform interpolation between these two curves.

Steps 12-22: Determine if current speed (RI08) is between curve 2 speed (M02) and curve 3 speed (M03). If not, then go to step 23. Otherwise, store hc values from curves 2 and 3 into M11 and M12, and speeds into M13 and M14. Go to step 42 to perform interpolation between these two curves.

Steps 23-33: Determine if current speed (RI08) is between curve 3 speed (M03) and curve 4 speed (M04). If not, then go to step 34. Otherwise, store hc values from curves 3 and 4 into M11 and M12, and speeds into M13 and M14. Go to step 42 to perform interpolation between these two curves.

Steps 34-41: Current speed (RI08) must be between curve 4 speed (M04) and curve 5 speed (M05). Store hc values from curves 4 and 5 into M11 and M12, and speeds into M13 and M14.

Steps 42-50: Perform the interpolation between the speeds in M13 and M14 and store the result to RO01.

Suction Flow Calculation Block F_SUCT

F_SUCT is a CALCA block that calculates the compressor suction flow via equations 3c, 4, and 5. The following connections are required:

RI01 = hc from performance curves (either PERF_CURVE.RO01 if variable speed compressor or PERF_CURV1.OUT if fixed speed)

RI02 = hc calculation factor from anti-surge controls (FLOW_SP.RO03)

RI04 = Flowing density factor at suction conditions from anti-surge controls (FLOW_SP.RI04)

RI05 = Maximum flow from anti-surge controls (FLOW_SP.RI05)

RI06 = Flowing density factor at orifice conditions from anti-surge controls (FLOW_SP.RI06)

BI01 = Compressor run indication

MA = :F_SUCT.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

TIMINI = 3

M02 = 100.0

The block generates the following outputs:

RO01 = Pressure ratio modified by performance factor

RO02 = Calculated pressure ratio

Note: If flow orifice is in the suction, then RI04 and RI06 are equal and cancel each other out.

Suction Flow Calculation Block Steps

STEP01 = IN RI01 ;PERF CURVE %HC

STEP02 = IN 0

STEP03 = MAX 2

STEP04 = DIV RI02 ;HC CALC FACTOR

STEP05 = OUT M18 ;PERF CURVE %HS

STEP06 = DIV M02 ;MAX H

STEP07 = SQRT

STEP08 = DIV RI04 RI06 ;SUCT / ORIF COMP

STEP09 = MUL RI05 ;MAX FLOW

STEP10 = IN BI01 ;COMP RUN

STEP11 = MUL 3

STEP12 = OUT RO01 ;COMP FT INPUT

STEP13 = END

DCS IMPLEMENTATION – PRESSURE SIMULATION

Pressure Simulation Block

The pressure simulation block is a CALCA block that performs the calculation in equation 7. The following connections are required:

RI01 = Total flow into pressure node

RI03 = Total flow out of pressure node

MA = Lock to auto

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

RI02 = Lag factor for flow into node (must be between 0 and 1)

RI04 = Lag factor for flow out of node (must be between 0 and 1)

RI07 = Maximum simulated noise (pressure units)

RI08 = Accumulation factor (Ka in equation 7)

BI01 = Initialization command (pressure is set to value in M12)

TIMINI = 3

M08 = 0.5

M09 = 1.0

M10 = Minimum pressure

M11 = Maximum pressure

M12 = Initialization pressure

The block generates the following outputs:

RO01 = Simulated pressure (with noise applied)

RO02 = Simulated pressure (without noise applied)

RO04 = Imbalance between flow in and flow out

BO01 = Initialization flag

M01 = Previous value of flow into node

M02 = Previous value of flow out of node

Pressure Simulation Block Steps

STEP01 = RCL BI01 ;INIT COMMAND

STEP02 = BII 5

STEP03 = OUT BO01 ;INIT FLAG

STEP04 = GTO 6

STEP05 = SET BO01 ;INIT FLAG

STEP06 = CST

STEP07 = IN BO01 ;INIT FLAG

STEP08 = BIT 14

STEP09 = SUB M09 RI02 ;1 – LAG FACTOR

STEP10 = MUL RI01 ;CURR INPUT

STEP11 = MUL RI02 M01 ;LAG * PREV INPUT

STEP12 = ADD 2

STEP13 = GTO 15

STEP14 = IN RI01 ;CURR INPUT

STEP15 = OUT M01 ;PREV INPUT

STEP16 = CST

STEP17 = IN BO01 ;INIT FLAG

STEP18 = BIT 24

STEP19 = SUB M09 RI04 ;1 – LAG FACTOR

STEP20 = MUL RI03 ;CURR INPUT

STEP21 = MUL RI04 M02 ;LAG * PREV INPUT

STEP22 = ADD 2

STEP23 = GTO 25

STEP24 = IN RI03 ;CURR INPUT

STEP25 = OUT M02 ;PREV INPUT

STEP26 = CST

STEP27 = SUB M01 M02

STEP28 = OUT RO04 ;FLOW IMBALANCE

STEP29 = CST

STEP30 = IN BO01 ;INIT FLAG

STEP31 = BIT 35

STEP32 = MUL RI08 RO04 ;ACCUM FACTOR

STEP33 = ADD RO02 ;PREV ACCUM

STEP34 = GTO 36

STEP35 = IN M12 ;INIT VALUE

STEP36 = IN M10 ;MIN ACCUM

STEP37 = MAX 2

STEP38 = IN M11 ;MAX ACCUM

STEP39 = MIN 2

STEP40 = OUT RO02 ;CURR ACCUM

STEP41 = CST

STEP42 = RAND ;RANDOM NO. (0 TO 1)

STEP43 = SUB M08 ;CONSTANT 0.5

STEP44 = MUL RI07 ;MAX NOISE

STEP45 = ADD RO02

STEP46 = OUT RO01 ;ACCUM W/ NOISE

STEP47 = END

Pressure Simulation Block Logic Details

Steps 1: Read and clear the block initialization command BI01. The value of BI01 is stored into the initialization flag BO01 in step 3.

Steps 2-5: If this is the block initialization pass (BII), then go to step 5 where the initialization flag BO01 is set.

Steps 7-15: If the initialization flag BO01 is on, then bypass the filtering calculation by going to step 14. Otherwise, perform the filtering calculation for the flow into the node. Filtering is done by taking a fraction (RI02) of the previous value (M01), one minus that fraction times the new value (RI01), and adding the two terms together. The filtered value is stored in M01.

Steps 17-25: If the initialization flag BO01 is on, then bypass the filtering calculation by going to step 24. Otherwise, perform the filtering calculation for the flow out of the node. Filtering is done by taking a fraction (RI04) of the previous value (M02), one minus that fraction times the new value (RI03), and adding the two terms together. The filtered value is stored in M02.

Steps 27-28: Calculate the flow imbalance and store the result to RO04.

Steps 30-31: If the initialization flag BO01 is on, then go to step 35 to set the pressure to the initialization value.

Steps 32-40: Multiply the accumulation factor (RI08) by the flow imbalance (RO04) and add the previous pressure (RO02). Limit the result to the minimum pressure (M10) and the maximum pressure (M11), and store the result to RO02.

Steps 42-46: Simulate noise by generating a random number (RAND) between 0 and 1, subtracting 0.5, and multiplying by the maximum noise level (RI07). Add the noise to the filtered flow (RO02) and store the result to RO01.

DCS IMPLEMENTATION – LEVEL SIMULATION

Level Simulation Block

The level simulation block is a CALCA block that performs the calculation in equation 8. It is identical to the pressure simulation block discussed previously. The following connections are required:

RI01 = Total flow into level

RI03 = Total flow out of level

MA = Lock to auto

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

RI02 = Lag factor for flow into level (must be between 0 and 1)

RI04 = Lag factor for flow out of level (must be between 0 and 1)

RI07 = Maximum simulated noise (level units)

RI08 = Accumulation factor (Ka in equation 8)

BI01 = Initialization command (level is set to value in M12)

TIMINI = 3

M08 = 0.5

M09 = 1.0

M10 = Minimum level

M11 = Maximum level

M12 = Initialization level

The block generates the following outputs:

RO01 = Simulated level (with noise applied)

RO02 = Simulated level (without noise applied)

RO04 = Imbalance between flow in and flow out

BO01 = Initialization flag

M01 = Previous value of flow into level

M02 = Previous value of flow out of level

Level Simulation Block Steps

The steps for the level simulation block are identical to those for the pressure simulation block.

DCS IMPLEMENTATION – HEATER OUTLET TEMPERATURES SIMULATION

Heater Outlet Temperatures Simulation Blocks

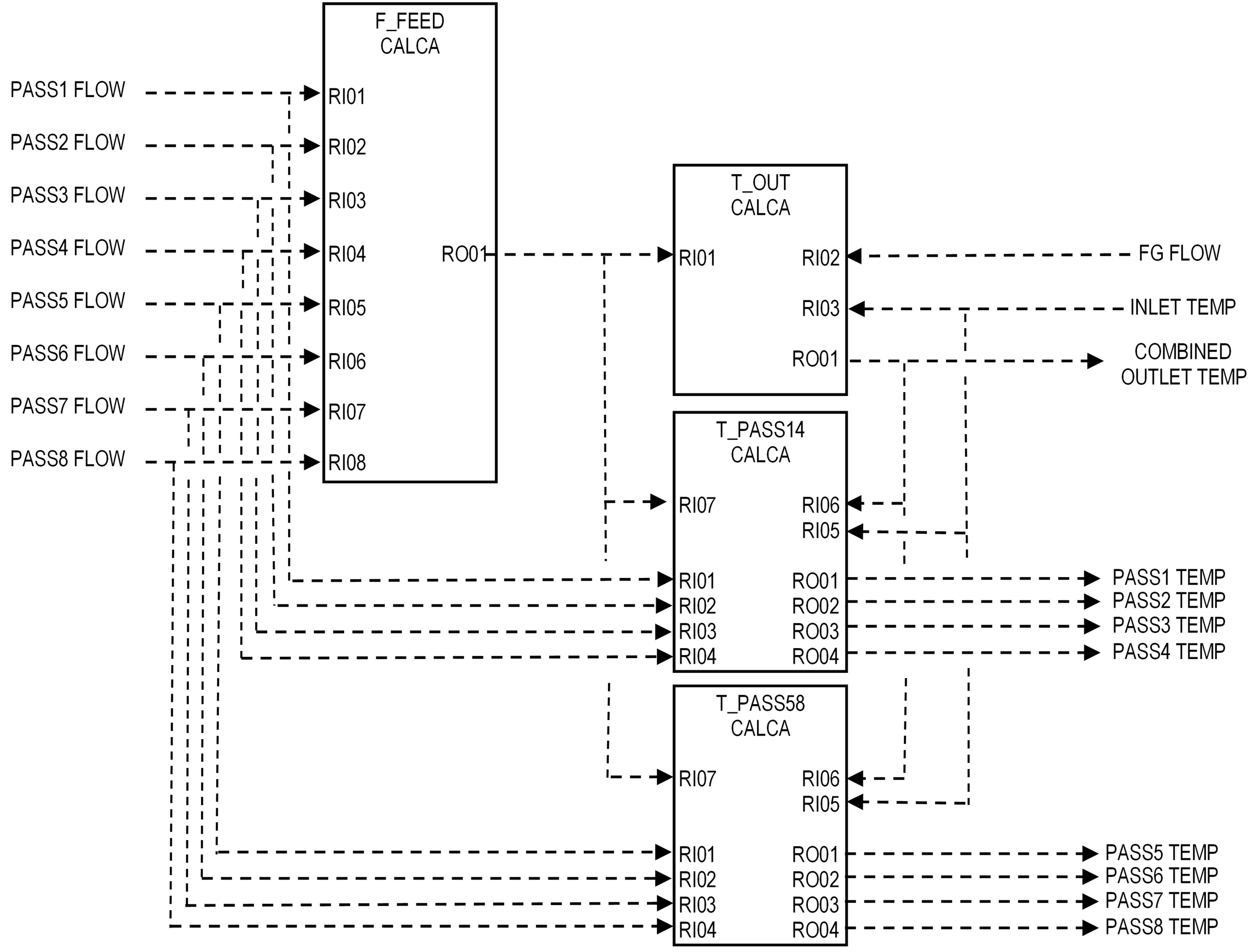

Figure 14 shows the block schematic for a typical heater outlet temperature simulation. The simulation includes the combined outlet temperature plus the individual pass outlet temperatures (up to eight passes). The application contains the following blocks (should be executed in this order):

- CALCA block for calculating total feed flow from the pass flows (F_FEED).

- CALCA block for calculating combined outlet temperature (T_OUT).

- CALCA block for calculating outlet temperatures for passes 1-4 (T_PASS14).

- CALCA block for calculating outlet temperatures for passes 5-8 (T_PASS58).

Total Feed Flow Block F_FEED

F_FEED is a CALCA block that calculates the total heater feed rate by summing the pass flows. This block can accommodate up to eight passes. The following connections are required:

RI01 = Pass 1 flow

RI02 = Pass 2 flow (lock to zero if only one pass)

RI03 = Pass 3 flow (lock to zero if less than 3 passes)

RI04 = Pass 4 flow (lock to zero if less than 4 passes)

RI05 = Pass 5 flow (lock to zero if less than 5 passes)

RI06 = Pass 6 flow (lock to zero if less than 6 passes)

RI07 = Pass 7 flow (lock to zero if less than 7 passes)

RI08 = Pass 3 flow (lock to zero if less than 8 passes)

MA = :F_FEED.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available.

TIMINI = 3

The block generates the following output:

RO01 = Total heater feed rate

Total Feed Flow Block Steps

STEP01 = ADD RI01 RI02 ;PASS1 + PASS2

STEP02 = ADD RI03 RI04 ;PASS3 + PASS4

STEP03 = ADD RI05 RI06 ;PASS5 + PASS6

STEP04 = ADD RI07 RI08 ;PASS7 + PASS8

STEP05 = ADD 4

STEP06 = OUT RO01 ;TOTAL FEED

STEP07 = END

Outlet Temperature Calculation Block T_OUT

T_OUT is a CALCA block that calculates the heater outlet temperature. The following connections are required:

RI01 = :F_FEED.RO01 (Total heater feed rate)

RI02 = Fuel gas flow

RI03 = Heater inlet temperature

MA = :T_OUT.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

RI06 = Fuel gas heating value (BTU/SCF)

RI07 = Feed heat capacity (BTU/B/DegF)

RI08 = Heater efficiency (%)

TIMINI = 3

M01 = Feed flow conversion factor (feed flow units to MB/D)

M02 = Fuel gas flow conversion factor (fuel gas flow units to MSCF/D)

M03 = 0.0

M04 = 100.0

M05 = Minimum denominator to prevent divide by zero (e.g., 0.001)

The block generates the following outputs:

RO01 = Heater outlet temperature

RO02 = Converted feed flow

RO03 = Converted fuel gas flow

RO04 = Temperature increase in heater

M20 = Heater efficiency converted from % to fraction

Outlet Temperature Calculation Block Steps

STEP01 = DIV RI08 M04 ;EFF / 100

STEP02 = OUT M20

STEP03 = MUL RI01 M01 ;FEED FLOW CONVERSION

STEP04 = MAX M03 ;LIMIT TO MIN ZERO

STEP05 = OUT RO02 ;CONVERTED FEED FLOW

STEP06 = MUL RI02 M02 ;FG FLOW CONVERSION

STEP07 = MAX M03 ;LIMIT TO MIN ZERO

STEP08 = OUT RO03 ;CONVERTED FG FLOW

STEP09 = CST

STEP10 = MUL RI06 M20 ;HT VAL * EFF

STEP11 = MUL RO03 ;FG FLOW

STEP12 = MUL RI07 RO02 ;HT CAPY * FEED FLOW

STEP13 = MAX M05 ;MIN DENOM

STEP14 = DIV

STEP15 = OUT RO04 ;TEMP INCREASE

STEP16 = ADD RI03 ;HTR INLET TEMP

STEP17 = OUT RO01 ;HTR OUTLET TEMP

STEP18 = END

Pass 1-4 Outlet Temperature Calculation Block T_PASS14

T_PASS14 is a CALCA block that calculates the heater pass outlet temperatures for passes 1-4. The following connections are required:

RI01 = Pass 1 flow

RI02 = Pass 2 flow

RI03 = Pass 3 flow (lock to zero if less than 3 passes)

RI04 = Pass 4 flow (lock to zero if less than 4 passes)

RI05 = Heater inlet temperature

RI06 = :T_OUT.RO01 (Heater outlet temperature)

RI07 = :F_FEED.RO01 (Total heater feed rate)

MA = :T_PASS14.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

TIMINI = 3

M01 = Pass 1 flow ratio at which pass outlet temperature will be equal to combined outlet temperature

M02 = Pass 2 flow ratio at which pass outlet temperature will be equal to combined outlet temperature

M03 = Pass 3 flow ratio at which pass outlet temperature will be equal to combined outlet temperature (set to 0.0 if sess than 3 passes)

M04 = Pass 4 flow ratio at which pass outlet temperature will be equal to combined outlet temperature (set to 0.0 if less than 4 passes)

M05 = Temperature conversion factor (1.8 if inputs are DegF and outlets are DegC; 1.0 if all are DegF)

M06 = Temperature conversion factor (32 if inputs are DegF and outlets are DegC; 0.0 if all are DegF)

M07 = Minimum pass flow to prevent divide by zero (e.g., 0.001)

The block generates the following outputs:

RO01 = Pass 1 outlet temperature

RO02 = Pass 2 outlet temperature

RO03 = Pass 3 outlet temperature

RO04 = Pass 4 outlet temperature

M11 = Pass 1 deviation from combined outlet

M12 = Pass 2 deviation from combined outlet

M13 = Pass 3 deviation from combined outlet

M14 = Pass 4 deviation from combined outlet

M15 = Converted heater inlet temperature

M16 = Converted heater combined outlet temperature

M17 = Overall heater delta temperature

Note: Heat balance among passes is altered by changing M01 – M04. Sum of all M01 – M04 (including passes > 4) must equal 1.0.

Pass 1-4 Outlet Temperature Calculation Block Steps

STEP01 = SUB RI05 M06 ;CONVERT DEGF->C

STEP02 = DIV M05

STEP03 = OUT M15 ;CONVERTED INLET

STEP04 = CST

STEP05 = SUB RI06 M06 ;CONVERT DEGF->C

STEP06 = DIV M05

STEP07 = OUT M16 ;CONVERTED OUTLET

STEP08 = CST

STEP09 = SUB M16 M15 ;OUTLET – INLET

STEP10 = OUT M17 ;HTR DELTA TEMP

STEP11 = CST ;PASS 1

STEP12 = MUL RI07 M01 ;TGT PASS FLOW

STEP13 = SUB RI01 ;PASS1 FLOW

STEP14 = MAX RI01 M07 ;PREVENT DIV BY 0

STEP15 = DIV

STEP16 = MUL M17 ;HTR DELTA TEMP

STEP17 = OUT M11 ;PASS DEV FM COMB

STEP18 = ADD M16 ;OUTLET

STEP19 = OUT RO01 ;PASS1 OUTLET

STEP20 = CST ;PASS 2

STEP21 = MUL RI07 M02 ;TGT PASS FLOW

STEP22 = SUB RI02 ;PASS2 FLOW

STEP23 = MAX RI02 M07 ;PREVENT DIV BY 0

STEP24 = DIV

STEP25 = MUL M17 ;HTR DELTA TEMP

STEP26 = OUT M12 ;PASS DEV FM COMB

STEP27 = ADD M16 ;OUTLET

STEP28 = OUT RO02 ;PASS2 OUTLET

STEP29 = CST ;PASS 3

STEP30 = MUL RI07 M03 ;TGT PASS FLOW

STEP31 = SUB RI03 ;PASS3 FLOW

STEP32 = MAX RI03 M07 ;PREVENT DIV BY 0

STEP33 = DIV

STEP34 = MUL M17 ;HTR DELTA TEMP

STEP35 = OUT M13 ;PASS DEV FM COMB

STEP36 = ADD M16 ;OUTLET

STEP37 = OUT RO03 ;PASS3 OUTLET

STEP38 = CST ;PASS 4

STEP39 = MUL RI07 M04 ;TGT PASS FLOW

STEP40 = SUB RI04 ;PASS4 FLOW

STEP41 = MAX RI04 M07 ;PREVENT DIV BY 0

STEP42 = DIV

STEP43 = MUL M17 ;HTR DELTA TEMP

STEP44 = OUT M14 ;PASS DEV FM COMB

STEP45 = ADD M16 ;OUTLET

STEP46 = OUT RO04 ;PASS4 OUTLET

STEP47 = END

Pass 1-4 Outlet Temperature Calculation Logic Details

Steps 1-3: Convert inlet temperature (RI05) from DegF to DegC if pass outlet temperatures must be in DegC and inlet is in DegF. The converted temperature is stored into M15.

Steps 5-7: Convert combined outlet temperature (RI06) from DegF to DegC if pass outlet temperatures must be in DegC and combined outlet is in DegF. The converted temperature is stored into M16.

Steps 9-10: Calculate the overall change in temperature across the heater (i.e., combined outlet – inlet) and store into M17.

Steps 12-19: Perform the calculations in equations 14 and 15 for pass 1. The pass flow (RI01) is limited to a minimum (M07) to prevent dividing by zero. The pass outlet temperature is stored in RO01.

Steps 21-28: Perform the calculations in equations 14 and 15 for pass 2. The pass flow (RI02) is limited to a minimum (M07) to prevent dividing by zero. The pass outlet temperature is stored in RO02.

Steps 30-37: Perform the calculations in equations 14 and 15 for pass 3. The pass flow (RI03) is limited to a minimum (M07) to prevent dividing by zero. The pass outlet temperature is stored in RO03.

Steps 39-46: Perform the calculations in equations 14 and 15 for pass 4. The pass flow (RI04) is limited to a minimum (M07) to prevent dividing by zero. The pass outlet temperature is stored in RO04.

Pass 5-8 Outlet Temperature Calculation Block T_PASS58

T_PASS58 is a CALCA block that calculates the heater pass outlet temperatures for passes 5-8. This block is not needed if the heater has less than 5 passes. The following connections are required:

RI01 = Pass 5 flow

RI02 = Pass 6 flow (lock to zero if less than 6 passes)

RI03 = Pass 7 flow (lock to zero if less than 7 passes)

RI04 = Pass 8 flow (lock to zero if less than 8 passes)

RI05 = Heater inlet temperature

RI06 = :T_OUT.RO01 (Heater outlet temperature)

RI07 = :F_FEED.RO01 (Total heater feed rate)

MA = :T_PASS14.MA.1 (lock to auto)

The block parameters must be set as follows:

PERIOD = Fastest execution frequency available

TIMINI = 3

M01 = Pass 5 flow ratio at which pass outlet temperature will be equal to combined outlet temperature

M02 = Pass 6 flow ratio at which pass outlet temperature will be equal to combined outlet temperature (set to 0.0 if less than 6 passes)

M03 = Pass 3 flow ratio at which pass outlet temperature will be equal to combined outlet temperature (set to 0.0 if less than 7 passes)

M04 = Pass 4 flow ratio at which pass outlet temperature will be equal to combined outlet temperature (set to 0.0 if less than 8 passes)

M05 = Temperature conversion factor (1.8 if inputs are DegF and outlets are DegC; 1.0 if all are DegF)

M06 = Temperature conversion factor (32 if inputs are DegF and outlets are DegC; 0.0 if all are DegF)

M07 = Minimum pass flow to prevent divide by zero (e.g., 0.001)

The block generates the following outputs:

RO01 = Pass 5 outlet temperature

RO02 = Pass 6 outlet temperature

RO03 = Pass 7 outlet temperature

RO04 = Pass 8 outlet temperature

M11 = Pass 5 deviation from combined outlet

M12 = Pass 6 deviation from combined outlet

M13 = Pass 7 deviation from combined outlet

M14 = Pass 8 deviation from combined outlet

M15 = Converted heater inlet temperature

M16 = Converted heater combined outlet temperature

M17 = Overall heater delta temperature

Note: Heat balance among passes is altered by changing M01 – M04. Sum of all M01 – M04 (including passes > 4) must equal 1.0.

Pass 5-8 Outlet Temperature Calculation Block Steps

The steps for block T_PASS58 are identical to those for T_PASS14.

DCS IMPLEMENTATION – HEAT EXCHANGER OUTLET TEMPERATURE SIMULATION

Exchanger Outlet Temperature Calculation Block T_EXCH

T_EXCH is a CALCA block that calculates the heat exchanger outlet temperature for the example in Figure 8. The following connections are required:

RI01 = Stream1 flow rate

RI02 = Stream1 inlet temperature (set to 1.0 if condensing steam)

RI03 = Stream1 outlet temperature (set to 0.0 if condensing steam)

RI05 = Stream2 flow rate

RI06 = Stream2 inlet temperature

MA = :T_EXCH.MA.1 (lock to auto)

The block parameters must be set as follows:

RI04 = Stream1 heat capacity (latent heat if steam)

RI07 = Stream2 heat capacity

TIMINI = 3

M01 = Stream1 flow conversion factor (e.g., 0.04167 for B/D to B/H)

M02 = Stream2 flow conversion factor

M03 = 0.0

M04 = Minimum denominator to prevent divide by zero (e.g., 0.001)

The block generates the following outputs:

RO01 = Stream2 outlet temperature

RO02 = BTU transferred

RO03 = Stream1 temperature decrease

RO04 = Stream2 temperature increase

M11 = Stream1 flow converted

M12 = Stream2 flow converted

Exchanger Outlet Temperature Calculation Block Steps

STEP01 = SUB RI02 RI03 ;STREAM1 INLET – OUTLET

STEP02 = MAX M03 ;LIMIT TO ZERO

STEP03 = OUT RO03 ;STREAM1 TEMP DECR

STEP04 = MUL RI01 M01 ;CONVERT FLOW

STEP05 = OUT M11 ;CONVERTED STREAM1 FLOW

STEP06 = MUL RI04 ;STREAM1 HT CAPY

STEP07 = MUL RO03 ;STREAM1 TEMP DECR

STEP08 = OUT RO02 ;BTU TRANSFERED

STEP09 = MUL RI05 M02 ;CONVERT FLOW

STEP10 = OUT M12 ;CONVERTED STREAM2 FLOW

STEP11 = MUL RI07 ;STREAM2 HT CAPY

STEP12 = MAX M04 ;LIMIT TO MIN DENOM

STEP13 = DIV

STEP14 = OUT RO04 ;STREAM2 TEMP INCR

STEP15 = ADD RI06 ;STREAM2 INLET

STEP16 = OUT RO01 ;STREAM2 OUTLET TEMP

STEP17 = END

DCS IMPLEMENTATION – GC ANALYZER SIMULATION

GC Analyzer Simulation Block A_GCSIM

A_GCSIM is a CALCA block that simulates a GC analyzer as shown in Figure 10. The analyzer samples a process stream and reports its composition at a set frequency, such as every three minutes. A_GCSIM acquires the simulated composition and updates its output at the analyzer cycle frequency to mimic an actual GC analyzer.

The following connections are required:

RI01 = Simulated composition

MA = :A_GCSIM.MA.1 (lock to auto)

The block parameters must be set as follows:

RI08 = GC analyzer cycle frequency (sec)

TIMINI = 3

The block generates the following outputs:

RO01 = Simulated composition updated at GC analyzer cycle frequency

M01 = GC analyzer cycle frequency (RI08 minus one)

GC Analyzer Simulation Block Steps

STEP01 = IN RI08 ;GC CYCLE TIME

STEP02 = SUB M02 ;CONSTANT 1.0

STEP03 = OUT M01

STEP04 = CST

STEP05 = BII 7 ;INIT LOGIC

STEP06 = GTO 10

STEP07 = CLR BO01 ;TIMER RESET

STEP08 = IN RI01 ;SIM COMPOSITION

STEP09 = OUT RO01 ;SIM GC SIGNAL

STEP10 = CST

STEP11 = IN BO01 ;TIMER RESET

STEP12 = OSP M01

STEP13 = OUT BO02 ;TIMER RUNNING

STEP14 = OR BO01 BO02 ;TIMER EXPIRED?

STEP15 = SSF BO01 ;TIMER RESET

STEP16 = CLR BO01

STEP17 = CST

STEP18 = IN BO02 ;TIMER RUNNING?

STEP19 = BIT 22

STEP20 = IN RI01 ;SIM COMPOSITION

STEP21 = OUT RO01 ;SIM GC SIGNAL

STEP22 = END

DCS IMPLEMENTATION – pH ANALYZER SIMULATION

pH Analyzer Simulation Blocks

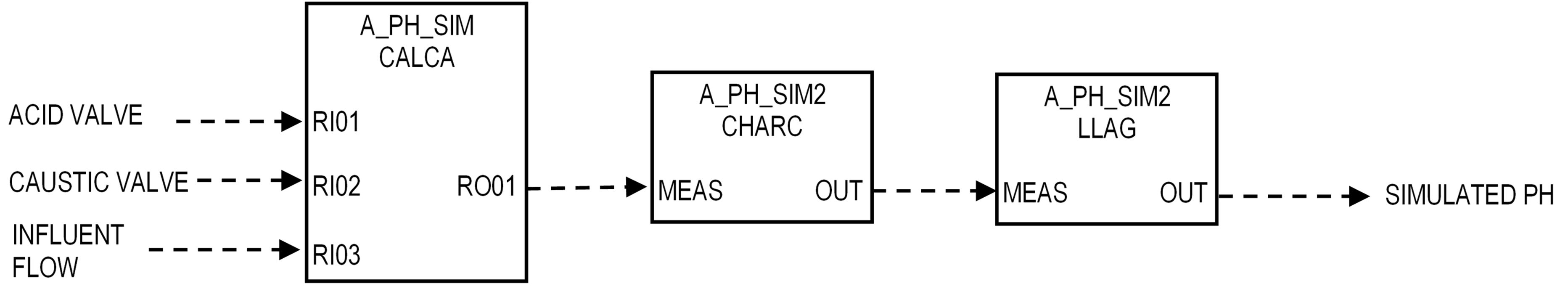

Figure 15 shows the block schematic for a typical pH simulation. The application contains the following blocks (should be executed in this order):

- CALCA block that linearizes the pH inputs using equation 20 and then blends them using equation 21 (A_PH_SIM).

- CHARC block that characterizes the pH versus the blended linearized pH (A_PH_SIM2).

- LLAG block that applies a lag to the calculated pH (A_PH_LAG).

pH Linearization Block A_PH_SIM

A_PH_SIM is a CALCA block that linearizes the pH inputs using equation 20 and then blends them using equation 21. The following connections are required:

RI01 = Acid valve position or flow

RI02 = Caustic valve position or flow

RI03 = Influent flow

MA = :A_PH_SIM.MA.1 (lock to auto)

The block parameters must be set as follows:

RI04 = Acid pH.

RI05 = Caustic pH.

RI06 = Influent pH.

TIMINI = 3

M01 = Acid flow factor for converting valve position to flow (1.0 if input is flow)

M02 = Caustic flow factor for converting valve position to flow (1.0 if input is flow)

M03 = Influent flow conversion factor (1.0 if conversion not necessary)

M04 = 10.0

M05 = -1.0

M06 = Minimum total flow (prevent divide by zero)

M07 = Value of SCALE in equation 20

M08 = 14.0

The block generates the following outputs:

RO01 = Effluent linearized pH

RO02 = Acid flow (calculated)

RO03 = Caustic flow (calculated)

RO04 = Influent flow (converted)

M10 = Total flow

M11 = Acid pH (linearized)

M12 = Caustic pH (linearized)

M13 = Influent pH (linearized)

pH Linearization Block Steps

STEP01 = MUL RI01 M01 ;ACID VLV * FLOW FAC

STEP02 = OUT RO02 ;ACID FLOW

STEP03 = MUL RI02 M02 ;CAUSTIC VLV * FLOW FAC

STEP04 = OUT RO03 ;CAUSTIC FLOW

STEP05 = MUL RI03 M03 ;INFLUENT FLOW * CONV FACT

STEP06 = OUT RO04 ;INFLUENT FLOW

STEP07 = ADD 3

STEP08 = OUT M10 ;TOTAL FLOW IN

STEP09 = CST

STEP10 = IN M04 ;CONSTANT 10

STEP11 = SUB RI04 M08 ;ACID PH -14

STEP12 = EXP

STEP13 = IN M04 ;CONSTANT 10

STEP14 = MUL RI04 M05 ;-PH

STEP15 = EXP

STEP16 = SUB

STEP17 = OUT M11 ;LIN PH ACID

STEP18 = CST

STEP19 = IN M04 ;CONSTANT 10

STEP20 = SUB RI05 M08 ;BASE PH -14

STEP21 = EXP

STEP22 = IN M04 ;CONSTANT 10

STEP23 = MUL RI05 M05 ;-PH

STEP24 = EXP

STEP25 = SUB

STEP26 = OUT M12 ;LIN PH BASE

STEP27 = CST

STEP28 = IN M04 ;CONSTANT 10

STEP29 = SUB RI06 M08 ;INF PH -14

STEP30 = EXP

STEP31 = IN M04 ;CONSTANT 10

STEP32 = MUL RI06 M05 ;-PH

STEP33 = EXP

STEP34 = SUB

STEP35 = OUT M13 ;LIN PH INF

STEP36 = CST

STEP37 = MUL RO02 M11 ;ACID FLOW * LIN PH

STEP38 = MUL RO03 M12 ;CAUSTIC FLOW * LIN PH

STEP39 = MUL RO04 M13 ;INFLUENT FLOW * LIN PH

STEP40 = ADD 3

STEP41 = IN M10 ;TOTAL FLOW IN

STEP42 = MAX M06 ;MIN FLOW

STEP43 = DIV

STEP44 = MUL M07 ;SCALE

STEP45 = OUT RO01 ;LIN PH EFF

STEP46 = END

pH Linearization Logic Details

Steps 1-2: Convert acid valve position into flow and store into RO02.

Steps 3-4: Convert caustic valve position into flow and store into RO03.

Steps 5-6: Convert influent flow to be compatible with acid and caustic flows and store into RO04.

Steps 7-8: Sum the three flows calculated above and store the total into M10.

Steps 10-17: Linearize the acid pH using equation 20 and store the result into M11.

Steps 19-26: Linearize the base (caustic) pH using equation 20 and store the result into M12.

Steps 28-35: Linearize the influent pH using equation 20 and store the result into M13.

Steps 37-45: Perform the calculation in equation 21. The total flow (M10) is limited to a minimum (M06) to prevent dividing by zero. The result is stored in RO01.

pH Characterizer Block A_PH_SIM2

A_PH_SIM2 is a CHARC block that characterizes the effluent pH versus the blended linearized pH from block A_PH_SIM. The following connections are required:

MEAS = :A_PH_SIM.RO01

MA = :A_PH_SIM2.MA.1 (lock to auto)

The following parameters must be set accordingly:

HSCI1 = 1

LSCI1 = -1

HSCO1 = 14.0

LSCO1 = 0.0

ENDP = 21

X_1 = -0.9999

Y_1 = 5.0

X_2 = -0.6308

Y_2 = 5.2

X_3 = -0.3979

Y_3 = 5.4

X_4 = -0.2508

Y_4 = 5.6

X_5 = -0.1579

Y_5 = 5.8

X_6 = -0.0990

Y_6 = 6.0

X_7 = -0.06151

Y_7 = 6.2

X_8 = -0.0373

Y_8 = 6.4

X_9 = -0.02114

Y_9 = 6.6

X_10 = -0.00954

Y_10 = 6.8

X_11 = 0.0

Y_11 = 7.0

X_12 = 0.00954

Y_12 = 7.2

X_13 = 0.02114

Y_13 = 7.4

X_14 = 0.0373

Y_14 = 7.6

X_15 = 0.06151

Y_15 = 7.8

X_16 = 0.0990

Y_16 = 8.0

X_17 = 0.1579

Y_17 = 8.2

X_18 = 0.2508

Y_18 = 8.4

X_19 = 0.3979

Y_19 = 8.6

X_20 = 0.6308

Y_20 = 8.8

X_21 = 0.9999

Y_21 = 9.0

Note: The characterizer values above correspond to a pH range of 5 to 9.

pH Lag Block A_PH_LAG

A_PH_LAG is a LLAG block that applies a lag to the pH from block A_PH_SIM2. The following connections are required:

MEAS = :A_PH_SIM2.OUT

MA = :A_PH_LAG.MA.1 (lock to auto)

The following parameters must be set accordingly:

HSCI1 = 14.0

LSCI1 = 0.0

HSCO1 = 14.0

LSCO1 = 0.0

LAGTIM = First order lag in pH response (minutes)

DCS IMPLEMENTATION – FIRED HEATER O2 ANALYZER SIMULATION

O2 Analyzer Simulation Block A_O2_SIM

A_O2_SIM is a CALCA block that calculates the oxygen % in the flue gas from a fired heater using equations 22-24. The following connections are required:

RI01 = Combustion air rate

RI02 = Fuel gas rate

MA = :A_O2_SIM.MA.1 (lock to auto)

The block parameters must be set as follows:

RI03 = Fuel gas O2 requirement for combustion

TIMINI = 3

M01 = 0.21

M02 = Air flow units conversion factor (1.0 if conversion not necessary)

M03 = Fuel gas flow units conversion factor (1.0 if conversion not necessary)

M04 = 100.0

M05 = 0.0

M06 = Minimum flue gas rate (prevent divide by zero)

The block generates the following outputs:

RO01 = Simulated flue gas oxygen %

RO02 = Net oxygen rate

RO03 = Oxygen supply rate from air

RO04 = Oxygen combustion rate

M11 = Flue gas rate

O2 Analyzer Simulation Block Steps

STEP01 = MUL RI01 M01 ;COMB AIR * 0.21

STEP02 = MUL M02 ;UNITS CONVERSION

STEP03 = OUT RO03 ;O2 FLOW

STEP04 = CST

STEP05 = MUL RI02 RI03 ;FUEL * O2REQ

STEP06 = MUL M03 ;UNITS CONVERSION

STEP07 = OUT RO04 ;O2 CONSUMED BY FUEL

STEP08 = CST

STEP09 = SUB RO03 RO04 ;O2 IN – O2 CONSUMED

STEP10 = MAX M05 ;LIMIT TO ZERO

STEP11 = OUT RO02 ;NET O2 RATE

STEP12 = CST

STEP13 = MUL RI01 M02 ;AIR RATE

STEP14 = MUL RI02 M03 ;FUEL RATE

STEP15 = ADD 2

STEP16 = OUT M11 ;FLUE GAS RATE

STEP17 = CST

STEP18 = MUL RO02 M04 ;NET O2 RATE * 100

STEP19 = IN M11 ;FLUE GAS RATE

STEP20 = MAX M06 ;MIN FLUE GAS

STEP21 = DIV

STEP22 = OUT RO01 ;PERCENT O2

STEP23 = END

O2 Analyzer Simulation Logic Details

Steps 1-11: Perform the calculation in equation 22. The air rate and the fuel gas rate each have factors for converting the flows to compatible units. The net oxygen rate is limited to a minimum of zero (M05) to prevent a negative rate. The result is stored in RO02.

Steps 13-16: Calculate the flue gas rate using equation 23. The result is stored in M11.

Steps 18-22: Calculate the percent O2 using equation 24. The flue gas rate in M11 is limited to a minimum (M06) to prevent dividing by zero. The result is stored in RO01.